Designing a trafficable solids trap

Effluent generated from dairy sheds and feedpads may include a variety of solids besides manure.

These include such things as:

- sticks

- cow hair

- grain

- straw

- farm debris

- wire

- gravel

- sand

- syringes

- string.

These objects should be removed from the effluent as they can damage pumps, block pipes and unnecessarily increase the rate of siltation in ponds, thereby reducing the effective storage capacity.

Trafficable solids traps filter out the coarse solids and debris within the effluent. The material collected in the trap can then be cleaned out with a front-end loader or rear scraper.

The installation of a trafficable solids trap is common practice and may be a preferred option when yard flood washing systems are used.

Solids traps are sized to capture and contain the large volume of water released from a flood wash tank or hydrant system, reducing the risk of solids and fibrous material entering the effluent storage system. Being able to control the water flow from yard washing will reduce the disturbance to the biological and chemical reactions that take place in an effluent storage pond.

Trafficable solids traps can be implemented into any effluent management system taking into account:

- water use

- herd size

- cleaning frequencies.

If managed correctly, the trafficable solids trap will work effectively and efficiently at separating liquids from solids, therefore simplifying the application to pasture processes.

When designing trafficable solids traps, a number of factors need to be considered:

- volume generated by dairy yard and feedpad wastewater and effluent needed for storage and separation

- positioning

- materials for construction

- vehicle access

- drainage

- cleaning frequency

- depth and slopes relative to other components of the effluent system

- physical management of the solids trap and solid manure stockpiling

- equipment available for cleaning

- pumping or gravity release of effluent

- configuration of weeping wall.

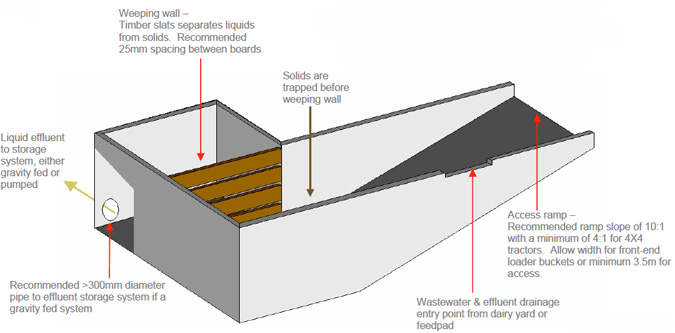

Figure 1: Trafficable solids trap

Design considerations

There are a number of variables to consider when designing trafficable solids traps.

The design is important in recognising these variables to be able to construct solids traps that will have:

- sufficient capacity

- works effectively

- is easily managed.

Volume required

Solids traps should be designed to take into account the volume of water used for each dairy or feedpad washdown and have allowance for the volume of effluent generated by the herd in the yard.

Constructing a trafficable solids trap that is larger than your immediate requirements will give flexibility for future changes to the dairy system.

Scenario 1, 2 and 3 details specifications for different sized trafficable solids traps based upon 3 typical farm situations.

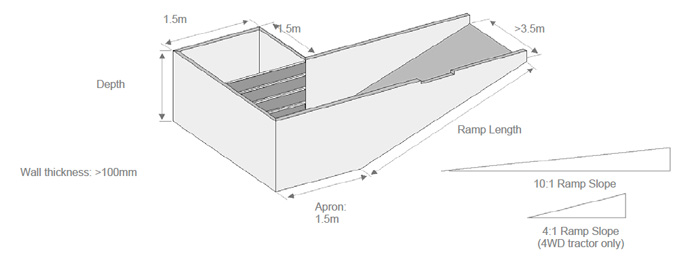

Figure 2 highlights the internal dimensions on a trafficable solids trap in relation to the 3 scenarios.

Contact your local Agriculture Victoria officer for help with calculating a solids trap for your dairy.

Scenario 1

A farm milks on average 100 cows and uses approximately 7000L per day to wash down the dairy yard.

| Volume of water used for dairy yard washdown | Cows milked | Days between cleaning | Depth | Overall length (ramp + apron) | Ramp length | Ramp slope | Total sump volume | Estimated concrete volume with wall width of 100mm |

|---|---|---|---|---|---|---|---|---|

(Litres) | (m) | (m) | (m) | (m3) | (m3) | |||

7000 | 100 | 30 | 0.68 | 8.3 | 6.8 | 10:1 | 8.2 | 6.2 |

Scenario 2

A farm milks on average 250 cows and uses approximately 13,000L per day to wash down the dairy yard.

| Volume of water used for dairy yard washdown | Cows milked | Days between cleaning | Depth | Overall length (ramp + apron) | Ramp length | Ramp slope | Total sump volume | Estimated concrete volume with wall width of 100mm |

|---|---|---|---|---|---|---|---|---|

13,000 | 250 | 30 | 0.95 | 11.0 | 9.5 | 10:1 | 16.0 | 8.7 |

Scenario 3

A farm milks on average 500 cows and uses approximately 30,000L per day to wash down the dairy yard.

| Volume of water used for dairy yard washdown | Cows milked | Days between cleaning | Depth | Overall length (ramp + apron) | Ramp length | Ramp slope | Total sump volume | Estimated concrete volume with wall width of 100mm |

|---|---|---|---|---|---|---|---|---|

30,000 | 500 | 30 | 1.43 | 15.8 | 14.3 | 10:1 | 36.0 | 13.6 |

These scenarios are samples only of potential trap sizes based on:

- predicted water use

- herd size

- 30-day cleaning frequency.

Trap designs need to be calculated for individual farm requirements.

Figure 2: Internal dimensions on trafficable solids trap

Vehicle access

Designs need to take into account the individual specifications of the vehicles needed to clean the trap. The ramp should be large enough for easy access and allow manoeuvrability for cleaning efficiency.

Access ramps have a recommended grade of 1 in 10 and a maximum grade of 1 in 4 (4WD tractors).

The width of the trap is set by the width of the cleaning vehicle and loader bucket. Allowance of at least 0.3 metres either side of the tractor should be made to allow for sideways movement during cleaning.

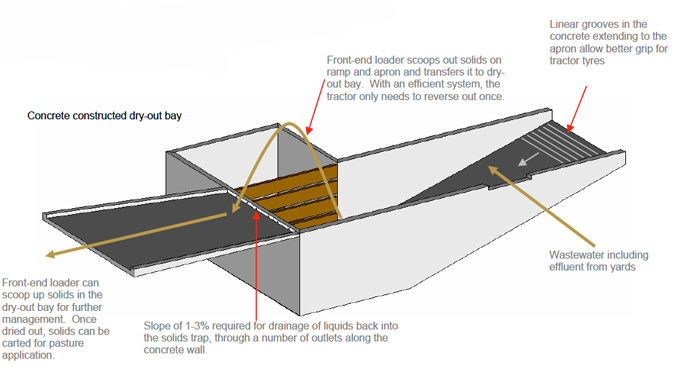

Traps should also have some type of grooving on the entry slopes to provide better traction as they have a tendency to become slippery.

Positioning

There are two important factors that influence the positioning of a trafficable solids trap.

Near dairy or feedpad waste water

The first factor being that the solids trap is positioned where dairy or feedpad yard wastewater including effluent is directed. This is the natural drainage course on the yard.

In most circumstances, the solids trap is either at the end of the yard or alongside it as these are the common drainage points.

Effluent running off yards should not be conveyed directly onto the weeping wall, as this will cause unnecessary blockages.

The preferred option is to create a vortex effect within the trap allowing incoming effluent to circulate. This tends to enable solids to be deposited in the middle of the trap away from the weeping wall.

Easy vehicle access

The second important factor is that the solids trap must be positioned where it can be managed efficiently and easily accessed by vehicle. The area around the solids trap should not limit management of liquids or solids. There should be adequate spacing for manure stockpiling and easy access for loading and removal from the site.

Materials

Trafficable solids traps are of concrete construction and should be designed to cope with the impacts entailed in cleaning then out.

Wall thickness should be a minimum of 25mm for each 300mm of wall height, but a thickness of between 100mm and 200mm is recommended. Steel mesh must be used for reinforcement of the concrete structure.

It is recommended that the weeping wall be constructed with wooden slats. These are preferred as they are better able to withstand the impacts involved in cleaning the solids trap out and are simple to replace if necessary.

As opposed to older trap designs weeping walls are now offset beside the trap to prevent damage during cleaning.

The weeping wall is set 1.5m off the back wall alongside the ramp wall. The wooden slats should have a spacing of 25mm. The spacing for individual traps can be set differently depending on the nature of the effluent and the discharge rate required.

Drainage

Trafficable solids traps should be designed to be self draining. A gravity fed solids trap to storage system should use a 300mm diameter discharge pipe, located at the base of the trap behind the weeping wall.

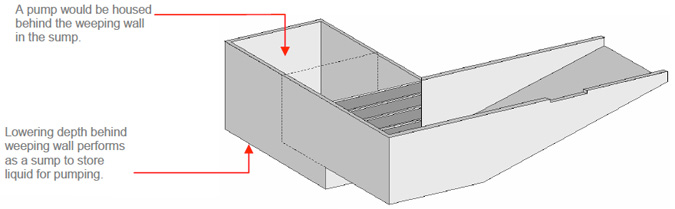

A pump-operated system can house the pump behind the weeping wall. This may necessitate changing the design of the trafficable solids trap to include a sump.

Figure 3: Trafficable solids trap with dry-out bay

Cleaning

The rate of solids accumulation in a solids trap depends on:

- number of cows milked

- materials used for laneway surfacing

- laneway condition

- concentration of solids in the effluent

- cow flow through the yard

- gap size between baffles.

On one farm with a 140 cow-milking herd the trap needed to be cleaned out every 4 to 6 weeks. Cleaning involved removing 10 full front-end loader scoops (3.1 cubic metres). This took between 30 to 45 minutes.

The weeping wall should be cleaned as needed using a rake or shovel for the spacing to effectively allow liquids through the solids trap.

A solids dry-out bay can be implemented into the trafficable solids trap design. Not only will it create better efficiency for cleaning and further management, but also ensures liquids drain into the sump, avoiding nutrient loss and leaching.

A trafficable solids trap simplifies the process of solids separation yielding high value manure as well as reducing solids entering the ponds, which are more difficult to manage. Uses for the manure could include:

- spread thinly over pastures to improve soil fertility

- apply to paddocks that require organic matter after laser grading

- preparation for crop or pasture sowing

- sell off-farm.

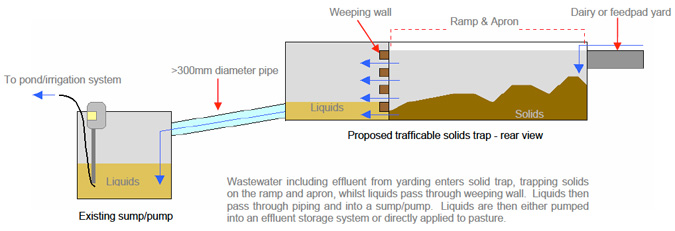

Trafficable solids traps used in conjunction with sump and pumps

Trafficable solids traps can be used in conjunction with pump and sumps. Placing trafficable solids traps before pumps and sumps will reduce silting of sumps as well as reducing wear on the pump.

When trafficable solids traps are installed before pumps and sumps, a number of factors will affect pump selection and performance.

Pump selection

Trafficable solids traps decrease the flow rate of effluent entering the trap thereby allowing suspended solids to drop out.

When selecting a pump or accommodating an existing one, this reduced flow rate has to be considered so the pump performance matches the discharge from the solids trap.

The optimum pump is one that pumps only slightly faster than the discharge from the solids trap. If it pumps much faster it could damage the pump by turning on and off too often, but one that is too slow will result in the sump overflowing.

The discharge rate of a solids trap can be adjusted to suit pump performance by changing the timber slat spacing of the weeping wall.

If a pump has to operate at a specific flow rate to operate an irrigator, and this is higher than the discharge rate from the solids trap, a larger sump or a storage pond should be used. The sump or pond should hold at least 3 days worth of wastewater and effluent generated in the dairy per milking. Extra storage is needed in case of pump failure.

Alternative solutions need to be in place in the event of a pump breakdown on the trap as often dairy pits with lower drainage pipes will be inundated with effluent water as the system banks up. Replacement pumps or temporary drainage solutions should be considered.

Pump mounting is also an important element to consider as inadequate cleaning may allow solids to enter the sump well affecting low mounted pumps. Pumps mounted too high don't allow the drawing effect on the weeping wall allowing liquid to flow through effectively.

Figure 4: Existing sump or pump and trafficable solids trap

Figure 5: Trafficable solids trap design with sump and pump

Structural specifications for trafficable solids traps

28 day concrete strength (minimum):

- F'c = 25 MPa, Preferred Strength (minimum) = F'c: 30 MPa

Reinforcement minimum yield strength = 450 MPa

Minimum wall thickness:

- 25mm per 300mm

Minimum reinforcement:

- Single layer of reinforcement

- Two layers of reinforcement

Single layer of reinforcement:

- 12mm diameter bars at 300mm spacing. Area of steel per metre width: 367 mm²/m (could also use 10 mm diameter bars at 200 mm spacing)

- Alternative you can use reinforcement mesh: F102 (square mesh) or F718 (rectangular mesh)

For two layers of mesh the layer on the unexposed face can be:

- 12 mm diameter bars at 450mm spacing or 10mm diameter bars at 300mm spacing. Area of steel per metre width: 267 mm2/m

- Alternatively you can use reinforcement mesh: F82 (square mesh) or F828 (rectangular mesh)

Recommended use of commercial formwork:

- Can use trench walls for external forming. Bar chains should be employed for placement of reinforcement.

Minimum cover for reinforcement:

- 40mm, preferred cover 50mm.

Trafficable traps also can be purchased precast from selected retailers however the capacity must suit the farm and management.

Other solid separation systems

There is no doubt including some form of solid separation component before setting up ponds prior to pondage is an advantage to managing dairy effluent. For example:

- less pond maintenance

- pump protection from stones and grit

- less pipe blockages.

Trafficable solids traps are one of many options available to remove solids, fibrous material and debris from the effluent stream.

Other methods may include:

- Sump or pumps

- dual trafficable traps

- drive through traps

- settling or agitation sumps

- screen separators

- screw presses

- earthen ditches.

Choosing the most appropriate method is dependent on many variables such as:

- herd size

- washdown system volumes

- feedpad contributions

- whether sand needs to be extracted

- pump type

- location.

Solid separation is an essential part of any effluent system and should be clearly addressed in an effluent management plan.

More information

For more information contact our offices:

Echuca — (03) 5482 1922

Ellinbank — (03) 5624 2222

Tatura — (03) 5483 1101

Maffra — (03) 5147 0800

Warrnambool — (03) 5561 9946