Minimising dairy shed effluent stream

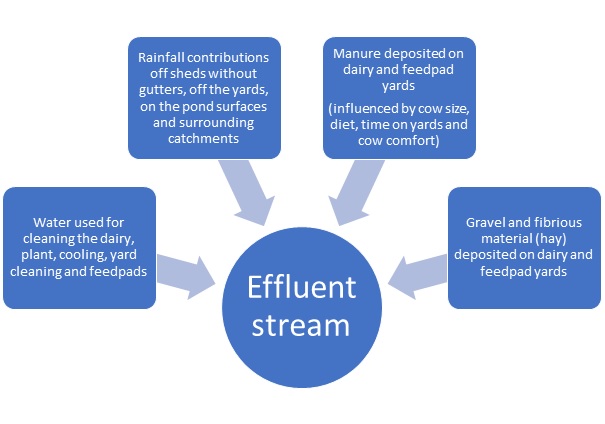

Minimising the amount of effluent generated helps to create an efficient effluent system and reduces the risk of ponds overflowing. To minimise the effluent stream, each contribution of effluent requires minimisation including manure, wash down water, rainfall, fibrous material, sand, gravel and debris.

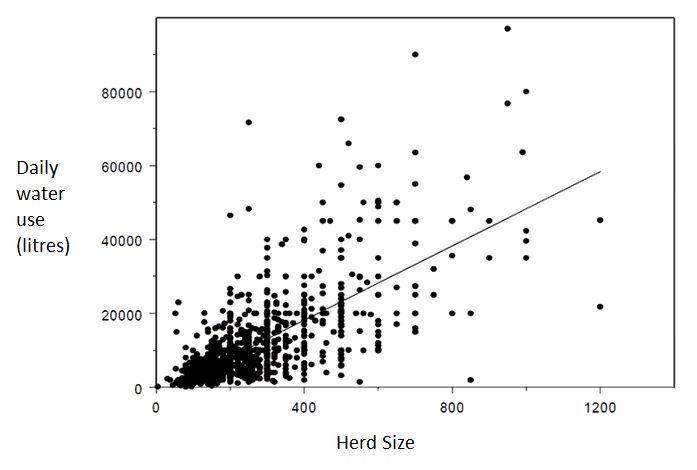

The amount of effluent generated at the dairy shed or intensive feeding facilities surprisingly is not necessarily related to the herd size or the size of the facility. Small herringbone dairies have been known to generate an effluent stream equivalent to large rotary operations where water use efficiency strategies are implemented. The volume of water used in the dairy will directly affect the recommended effluent storage pond capacity and the cost and time then needed to manage the effluent. Figure 1 illustrates the variation of water use across 780 dairies.

The purpose of this information is to explore the various components that impact on the effluent system and provide practical solutions to minimise their contribution to the total effluent volume. Figure 2 provides an illustration of the key components that impact on the effluent system.

Dairy shed water use

Minimising the volume of water used in the dairy shed and feedpad for cleaning will flow on to reduce the volume of effluent produced per year.

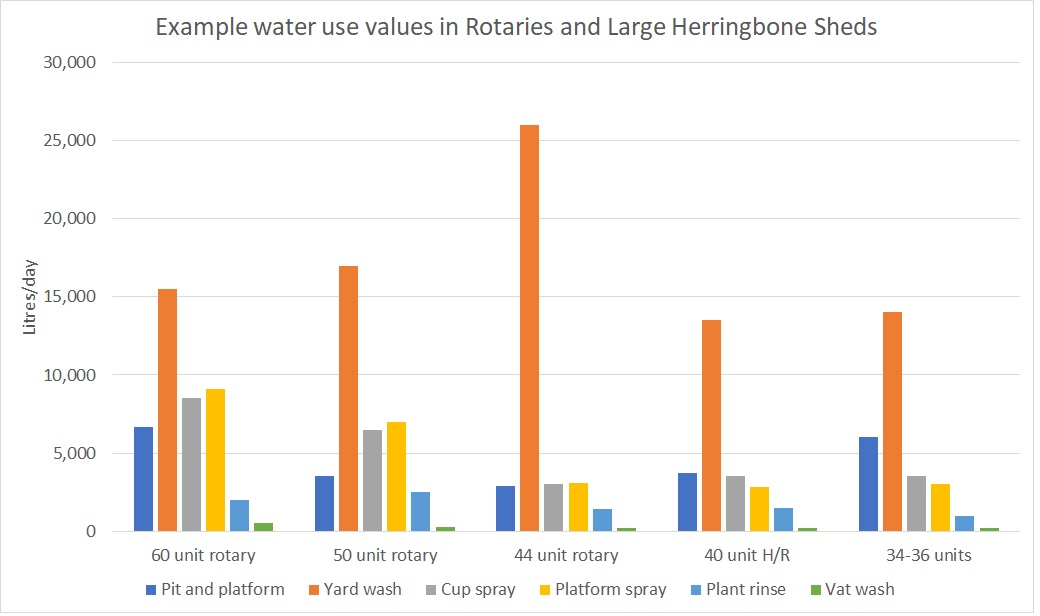

Understanding the volume of water used in each process in the dairy such as water for cleaning yards, platform sprays, plate cooler, etc. is important as it provides an opportunity to review and reduce each component. It also ensures the farm water reserves are sufficient to maintain the dairy and/or feedpad operation all year. Refer to Measuring Water Use in the Dairy Information Note for instructions on how this can be measured.

Aspects that use more water in the dairy involve processes that use high volumes of water such as a flood wash tank or processes that run for long periods of time, such as platform sprays in rotary sheds. Water used for the plate-cooler is one of the largest uses of water in the dairy and most dairies now recycle this water.

Maintaining plant and yard hygiene is essential, therefore water minimisation in the dairy should not compromise milk quality or herd health.

Practical options to reduce water use may include:

- Utilising recycled effluent from a multiple pond system to wash down holding yards and feedpads.

- Mechanical breakdown of manure prior to hosing or floodwash cleaning.

- Turning off cup and platform sprays immediately after cows have left the platform and reducing unnecessary volumes. Using timers on platform sprays to run them intermittently. These two components contribute nearly 40% of total daily water use in rotary sheds.

- Installing appropriate floodwash tanks to suit the yard washing requirement and positioned strategically to optimise performance. Where possible using recycled effluent through the floodwash.

- Repairing and replacing broken nozzles or leaking hoses and when upgrading appliances considering adopting water efficient technologies.

- Set up a system to store and reuse plate cooler water. If plate cooler water is diverted to a holding tank for yard cleaning ensure the overflow from this tank is recirculated so the water can be used or diverted to a dam, rather than flowing into the effluent system.

- Scraping manure off feedpads rather than cleaning with fresh water or using recycled water for cleaning.

Rainfall

Rainfall is another source of water that can enter the effluent system and unnecessarily fill storage ponds. Effluent storage ponds should be designed using the 90th percentile rainfall contributions entering the system to prevent them from overflowing during heavy storm events.

Options to reduce rainfall entering the effluent system may include:

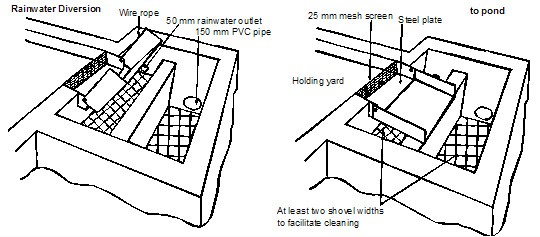

- Installing rainwater diversion off holding yards in high rainfall areas. Trap doors and diversion pipes installed on spoon drains or off yards prior to the solids trap or sump/pump are common (Figure 4). Manure and effluent must be cleaned before any rainfall diversion can be activated.

- Ensuring that the nib walls around the yard are high enough to prevent surface runoff from surrounding areas entering the yard.

- Rainwater tanks capturing roof runoff. This will reduce the contribution off the dairy shed roof and at the same time provide a reliable quality water supply.

- Levy banks or drain diversion around the pond(s). This will eliminate rainfall from surrounding paddocks and laneways entering the storage unnecessarily.

Manure load into the effluent system

The volume of effluent entering the effluent system is influenced by the size of the animal, amount of time the cow is spending on surfaces that drain into the system, and cow comfort.

Depending on yarding time and shed design most dairy herd will spend 10-15% of their time each day at the dairy. This increases substantially if a feedpad is in use. A herd that is unsettled and stressed in their environment will often deposit more manure than a herd that is content and comfortable. Design criterion should consider cow flow, comfort, operator ease and stock handling management for facility and yard design.

Options to improve animal well-being and cow comfort which therefore help to reduce the manure load may include:

- Providing adequate shading and protective tree belts or sprinklers and yard sprays to reduce heat stress.

- Vector control (Flies).

- Establishing adequate drainage to keep the area dry.

- Maintaining sufficient water supplies.

- Ensuring manure and feed spoilage is removed from the area periodically.

- Appropriate yard spacing per animal.

- Appropriate yarding width, length and slope to promote effective yard washing.

- Yard surfacing and patterning.

- Wide gateways to prevent cow bullying.

- Avoidance of sharp angles for cows exiting the shed.

- Appropriate yard design and location of gates to enhance cow flow and effective drafting.

For more information relating to feedpad design please see Guidelines for Victorian Dairy Feedpads and Freestalls.

Reducing the nutrient load of manure and urine entering the effluent stream

The herd diet will also influence the nutrient loading in the manure and urine once it’s excreted as there is a strong correlation between supplementary feeding intake and nutrient output. The nutrient content of the effluent will then have implications for application rates of effluent to pasture. Excessive feeding of crude protein (CP) and phosphorus (P) to dairy cows increases nitrogen (N) and phosphorus loads in manure, which can exacerbate the potential nutrient loss. The manipulation and adjustment of feed rations without compromising herd productivity or herd health has the potential to reduce both phosphorus and nitrogen levels being deposited in the effluent stream. This level of detail may be more applicable for the larger intensive herds operating on small acreages or on properties with extensive networks of watercourses and drainage lines.

Gravel and foreign material entering the effluent stream

Solids entering the effluent stream have the potential to cause problems whether it be with pumps, conveyance piping or within the ponds. Separation of the liquid and solid effluent stream will be necessary at some stage within the overall effluent system. Some farmers opt to utilise sumps and traps with weeping walls prior to pondage whilst others prefer to use settling ditches and ponds before conveying the liquid fraction into storage ponds.

The amount of these solids entering the effluent system can be reduced by:

- Keeping laneways well drained and in good condition. This will prevent cows transferring large amounts of stones and gravel into the holding yard.

- Placing foot baths immediately before the entry point to the yard.

- Installing a debris trap or screen below the yard and prior to any pond or pumps to collect fibrous material and other debris such as hair, tail tape, horns and string.

- Installing weeping walls or weir type structures to remove solids from the liquid stream.

References

Dairy Australia 2008, Effluent and Manure Management Database for the Australian Dairy Industry, accessed 9 June 2021

Department of Primary Industries 2009, Dairy Shed Water how much do you use?, accessed 31 May 2021