Producer case study: Bruce, Julie and Campbell Spittle

Bruce and Julie Spittle and their son Campbell, run a mixed cropping and grazing property at Ascot near Ballarat, Victoria, in addition to their property near Wentworth, NSW.

The Spittles’ Ascott farm was one of 4 properties from the Pyrenees and Smeaton BestWool/BestLamb groups to participate in the ‘Precision soil mapping in central Victorian pastures’ Producer Demonstration Site (PDS) project. The project investigated the potential of grid sampling soil to assess nutrient variability to tailor variable-rate applications (VRA) of fertiliser and ameliorants to grazing systems.

The Spittles found that being a host site provided an opportunity to gain insights into their pasture and soil fertility, and for them, along with the other producers involved, to assess whether VRA could be cost effective to help improve productivity.

Soil characteristics and nutrient levels across grazing paddocks can be highly variable. Factors such as the underlying variation in soil type, previous management, water movement, stock camps and uneven return of dung and urine across a paddock result in substantial variability in soil nutrient status. Grid soil mapping provides a one pass, laboratory analysed method of testing a paddock for variability in pH and nutrient levels. It is currently the most accurate method for developing VRA, which use variable-rate technology to match fertiliser rates to pasture requirements across an entire paddock. This approach is widely used in the cropping industry but has seen limited uptake in grazing systems in central Victoria despite potential to improve fertiliser efficiency.

The site

The Spittles’ Ascot property is a mixed cropping and grazing enterprise comprising of 700 cross-bred ewes stocked at approximately 10 dry sheep equivalent (DSE)/ha. The mixed system allows for summer stubble grazing, and their pasture system is based on phalaris and clover.

The Spittles’ demonstration site used VRA technology for the application of lime and gypsum.

Soil testing is usually undertaken annually and 40kg/ha mono ammonium phosphate (MAP) or single superphosphate (SSP) equivalent is applied to pastures. Lime is applied every five years and incorporated in the pasture renovation program. The renovation program begins with a spray graze, followed by an oat/hay crop, then a summer fodder crop, followed by an oat crop, and finally a perennial pasture.

Method

Grid based soil sampling was used to assess variability in soil nutrients across representative grazing paddocks at each of the four PDS host farms. All paddocks were grid soil sampled at 0–10cm depth at a 1ha resolution (to best understand in-paddock variability) in December 2020.

Soil samples were tested for pH, Olsen phosphorus (P), sulfur (S) and exchangeable cations (potassium (K), magnesium (Mg), sodium (Na), calcium (Ca)) at an accredited soil laboratory. Sub-soil samples were also collected at lower resolution (approximately every 10th grid square, targeted based on initial results) in 0–5 cm, 5–10 cm, 10–15 cm and 15–20 cm increments to allow for identification of any pH stratification issues.

A farmer steering committee developed paddock targets to address limitations to pasture production. Paired-paddock demonstrations were established to compare VRA versus the control which involved conventional blanket applications of key inputs (P, K, lime or gypsum). Application rates for the conventional applications were determined by the steering committee (using industry ‘rules of thumb’), based on a single set of soil test results (the paddock average from grid sample points) to achieve the target level.

Similar management was used across the paired paddocks, including similar grazing strategies. Pasture composition, feed on offer, stocking rate and pasture quality were monitored throughout the project to assess any impact on livestock and pasture production.

The benefits and costs of using VRA versus conventional blanket (control) applications when applying key pasture inputs were assessed by comparing the costs and relative pasture production (benefits) of the two systems.

Soil targets for the site included increasing pH to 5.5 and reducing exchangeable sodium percentage (ESP) to less than 6%. The paddock treatments included:

- Lime: the control received the district ‘rule of thumb’ of 2.5t/ha. The VRA paddock received a variable application calculated to pH 5.5 across the paddock, which equated to an average of 3.1t/ha.

- Gypsum - control paddock received district ‘rule of thumb’ of 2.5 t/ha. The VRA paddock received a calculated rate to reduce ESP to less than 6% -assuming a 60% efficiency in the displacement of sodium from the soil. This averaged 0.9t/ha across the paddock. Return soil sampling was undertaken three years later (2023) to assess any changes in soil conditions.

Results

Soil test results

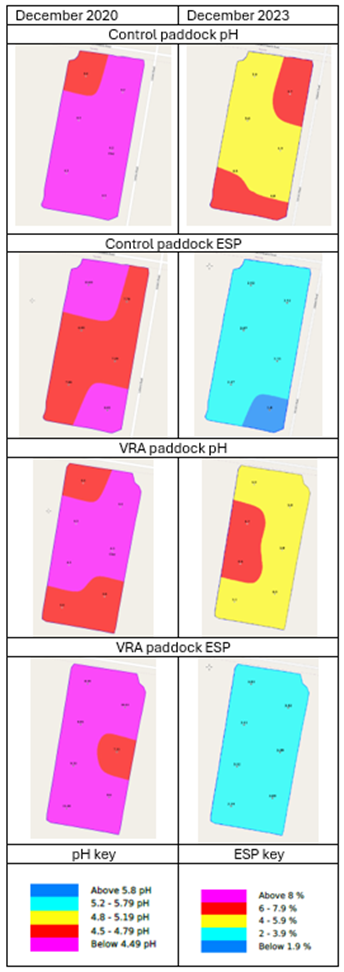

Figure 2 shows the initial 2020 and the 2023 soil test results.

Lime

The control paddock started with an average pH of 4.3 (range 4.2–4.6) in 2020, which increased to 4.9 (range 4.7–5.0) in 2023 after receiving 2.5 t/ha. The VRA paddock increased in pH from an average of 4.4 (range 4.3–4.6) in 2020 to 4.9 (range 4.6–5.1) in 2023 after receiving an average of 3.1t/ha. Both paddocks fell short of the 5.5 pH target and there was little change in the variability in soil pH.

Gypsum

Both the control and VRA gypsum applications effectively reduced the ESP across the paddock to less than 6%, and both exceeded the target. The control started with an average ESP of 8.7% (range 7.0–13.8%), which was reduced to 2.9% (range 1.8–3.9%) through an application of 2.5t/ha. The VRA started with an average of 9.2% (range 7.3–11.3%), which reduced to an average of 3.2% (range 2.2-3.9%) through the average application of 0.9 t/ha.

Pasture response and production

No consistent difference was measured in pasture production, stocking rate, pasture quality or pasture composition between the control and VRA paddocks throughout the demonstration. The Spittles’ VRA site grew an estimated extra 0.2t dry matter (DM)/ha across the three years, which would not be statistically significant. This indicated that no additional benefit was measured in the VRA paddock compared to the control paddock.

Economic outcomes

The economic analysis focused on the costs relative to the pasture production in the VRA and control paddocks. The results presented in Table 1 show that there were large differences in the soil sampling cost between the two treatments, with the 5.9ha VRA paddock equating to $442.50 (compared to a single soil test cost). Outside of this project, commercially, a 2ha grid size ($40/ha) in Central Victorian pastures has been found to best balance costs and meaningful outcomes.

Ameliorant costs were higher in the control paddock. This is due to the ‘rule of thumb’ gypsum application of 2.5t/ha being a higher rate than was required to bring ESP below 6%. By comparison, the VRA paddock had an application rate average of 0.9t/ha, incurring a lower application cost. The increased rate of gypsum in the control meant that the paddock finished at a lower ESP than was required to hit the target. The rate and cost of lime for the control (2.5t/ha) was lower than the VRA (averaging 3.1t/ha).

Table 1: Comparison of 3-year (2021 to 2023) costs and pasture growth of the 2 soil management treatments

Control | VRA | |

|---|---|---|

Total soil sampling cost ($/ha) | $14 | $75 |

Total capital fertiliser and ameliorate cost ($/ha) | $311 | $219 |

Total maintenance fertiliser cost ($/ha) | $159 | $159 |

Total treatment cost ($/ha) | $485 | $453 |

Total 3-year pasture growth (tDM/ha) | 15.6 | 15.8 |

Total treatment cost ($/tDM) | $31 | $29 |

The savings from reduced fertiliser/ameliorant application on the VRA paddocks were offset by the higher sampling cost of VRA. These results demonstrate the benefits and costs of additional information. This is partly a result of the law of diminishing returns to extra inputs. This principle also applies to extra inputs of information to production decisions, as demonstrated by intensive point sampling relative to transect sampling.

Producer feedback

Despite no clear economic benefits, Bruce said he could see advantages in grid sampling: ‘We all have pastures that range from weak areas to very productive areas. Precision agriculture gives us the knowledge and confidence to enhance our pastures to their potential. The system works best with accurate soil testing and professional nutrient advice with the right species that suit the environment.

‘One of the benefits of being a PDS host is that it made us answerable to the team for our grazing management, which was a good thing.

‘We recorded stock in and out and were given the tools to assess our feed on offer and the nutritional requirements of the stock. Our involvement gave us the chance to follow the trial from the start to the end and watch in real time for improvements between the test and control paddocks. Precision agriculture can be a little daunting, but the outcome from improving your soil can only be positive.’

Summary

- Grid soil sampling provided detailed soil information and identified moderate variability in ESP and low variability in pH across this site.

- Soil amelioration through both the VRA and control (blanket application) lime fell short of the target of pH 5.5 (both achieving an average of pH 4.9).

- Both the ‘standard’ application of 2.5 t/ha gypsum to the control and the VRA application (which averaged 0.9 t/ha) were more than required and the target (less than 6% ESP) was exceeded. (However, the overall benefit of lower ESP will offset the short-term cost of exceeding the ESP target.)

- Whether using a single soil test or grid mapping, calculating required applications rates (or seeking assistance e.g. from an agronomist) rather than applying ‘rules of thumb’, can help to cost effectively meet paddock targets. In hindsight, the control would have benefited from applying less gypsum and investing the savings into additional lime.

- The demonstration highlighted the importance of resampling paddocks over time to understand trends and impacts of applications (and animal movements within paddocks and across the farm).

- No obvious or consistent differences were measured in pasture production, quality and composition and stocking rate between the control and VRA paddocks.

- Grid sampling provided an increased level of soil information at an increased cost ($75/ha) compared to the control ($14/ha or $84 for one test). However, the grid sampling cost would be significantly less for a commercial 2 ha grid approach, at a reduced level of detail.

Note that this site demonstrated VRA for ameliorants (gypsum and lime) only, rather than fertiliser applications. VRA fertiliser applications were made at other sites with different outcomes, impacted by the movement of nutrients into sheep camps.

Acknowledgements

Thanks to Bruce, Julie and Campbell Spittle (and other site hosts) for allowing the demonstration to be conducted on their property, and the Pyrenees and Smeaton BestWool/BestLamb groups for their participation in the project.