Mole drainage systems

Mole drainage, on the right soil type and when installed correctly, can help reduce waterlogging problems substantially.

Mole drainage is widely used in New Zealand and the United Kingdom in heavy soils to improve productivity of pastures and crops. Mole drainage was popular with dairy farmers in the 1960s in Victoria but these often failed due to reasons now more fully understood. Recent research has resulted in robust guidelines for installing mole drains so they are more effective for longer, with a greatly reduced failure rate.

What is a mole drain?

Mole drains are unlined channels formed in clay subsoil. They're formed by pulling a ripper blade (or leg) with a cylindrical foot (or torpedo) attached on the bottom through the subsoil. A plug (or expander) is often used to help compact the channel wall. The foot is usually chisel-pointed and the entire point is hard-faced by welding. More frequent hard-facing of the underside will increase the effective life of the torpedo. The beam is the main rail that carries the leg and torpedo.

Mole drains are used in heavy soils where a clay subsoil near moling depth (400 to 600cm) prevents downward movement of ground water. Mole drains are a more sophisticated drainage system than open drains. Mole drains do not drain groundwater but remove water as it enters from the ground surface.

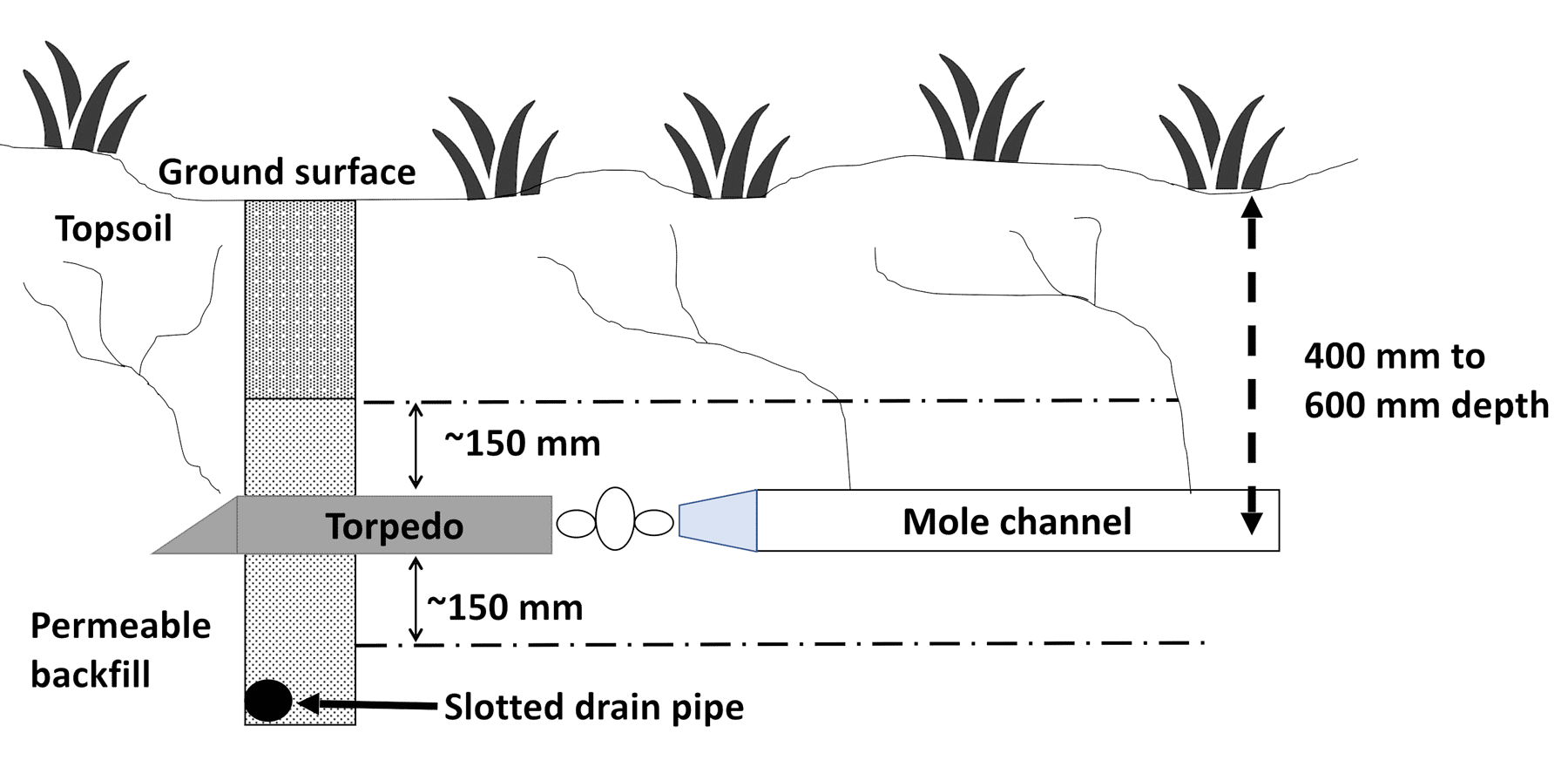

Mole drains over a collector pipe system

A mole drain over a collector pipe system is recommended in:

- soils where mole drains would have a very short lifespan due to sandy or stoney areas

- heavy clay type soils, or

- lengths greater than about 80 metres to reach an outfall

This system requires the installation of slotted subsurface drainage pipes at approximately 60m to 100m apart, across which mole drains are pulled. This system is useful where soil may contain stones or sandy patches in the profile, at drainage depth, which could collapse when moled. The relatively close spacing of the pipes and shorter mole drain lengths will minimise the area affected by the resultant poor drainage when the mole drain collapses.

Permeable backfill such as washed sand, small screenings or small diameter 'pea' gravel is placed (backfilled) on top of the slotted pipe in the base of the trench. The collector pipe will have been installed using a laser to ensure a constant fall in the pipe to the outfall. Depending on the clay content and its depth, this backfill must reach at least 150mm above the moling depth so that the water moves into the backfill via the mole channel.

Mole drains are then installed at an angle (often 70 to 900) to the direction of the pipes. Excess ground water flows into and along the mole drains, then drains into the porous backfill above the pipes, and is then quickly removed to outfalls via the subsurface collector pipes.

Types of mole ploughs

Well-designed mole draining ploughs allow the torpedo, when properly set, to maintain itself at the set depth almost irrespective of small ground surface irregularities. The front of the mole plough usually has skids to support the front of the beam, but the body of the beam floats clear of the ground. This allows the blade and torpedo some degree of movement to produce a smooth gradient within the limits of the under-beam clearance.

Trailed mole ploughs

Trailed mole ploughs require higher horsepower tractors than other mole ploughs because this design actually scrubs the ground when being pulled. But they produce more even grades than three-point linkage ploughs because of the longer beam (greater than 1.35m). They are more difficult to manoeuvre compared to the linkage plough but are now being replaced by semi tractor-mounted designs.

This plough has been used experimentally in Victorian trials but none are available commercially. They are more expensive to build than the other plough types.

Semi tractor-mounted mole ploughs

Although mounted on the tractor three-point linkage, these act as trailing ploughs when working and even out the mole gradient despite ground variation. The longer beam, coupled to a chain with a floating top link, allows a more even mole channel to be formed.

Fully tractor-mounted mole plough

The blade is mounted directly to the three-point linkage, so this type of plough is inexpensive to build and convenient to use. This design of mole plough produces more uneven grades than the trailed ploughs because of the short beam and is one reason for many mole drain failures.

The angle of the torpedo is influenced by the draught control of the tractor, so not free to find its own level. Also, being mounted so close to the rear wheels, the torpedo forms a mole channel as dictated by the ground surface undulations.

Ideally the torpedo should be allowed to 'float' with no pressure control used to make it go deeper. When traction is lost, the linkage arms lift the mole plough to reduce downward pressure, regaining traction as a result.

Automatic draught control is used on most tractors to improve traction. The fully tractor-mounted mole ploughs are better suited for smaller tractors and small areas but are only suitable for even ground surfaces.

Gravel mole ploughs

Gravel mole ploughs incorporate a hopper to allow finely graded gravel to fall into the mole channel. These ploughs have been used successfully in the UK in heavy soils that cannot hold 'normal' mole drains.

Experimental results from north east Victoria and Gippsland show they have promise on unstable clay soils, but are expensive because of the amount of gravel and close spacing needed. Unfortunately, very few of these machines exist in southern Australia.

Tractor power requirements for installing mole drains

Four-wheel drive tractors of approximately 60 to 80kw minimum power are recommended for installing moles. Crawler tractors of lesser power (above 45kw) are also suitable. The deeper the mole drain to be installed and the drier the soil, the greater the tractor power required.

Speed of mole ploughing

Recommended speed is 2 to 4km per hour. If pulled too fast, say 5 to 6km per hour, the plug can disrupt or tear the walls of the channel resulting in failure within 1 to 2 years.

Soil suitability for mole drainage

Soils should have a clay content in the range of 30 to 35 per cent to ensure long-lasting mole channels. A soil with a clay content above this range is likely to collapse quickly due to swelling or shrinking as they 'wet up' and 'dry down'.

Clay gives the soil the ability to hold together and reduces the chances of it collapsing after the mole is pulled. Sand content should be less than 30 per cent.

Ideally, the soil should be free of stones at the mole drain depth. If not, ensure the soil at moling depth is fairly wet so stones are more easily pushed aside by the plough torpedo or plug.

Testing of suitability for mole draining

Although not always foolproof, there are simple tests can that indicate a soil's suitability for mole drainage. See 'Determine the soil's suitability for mole drainage' on the page Which subsurface drainage system to use for more information.

It is wise to consult a subsurface drainage expert and, failing that, only mole drain a small area initially to gauge the likelihood of success in the long term.

When to mole drain

To achieve satisfactory results, the soil in the vicinity of the mole channel needs to be moist enough to form a channel. The soil must not be dry enough to crack and break up, and not soft enough to slough off and form a slurry. These conditions usually occur during the drying cycle in late spring to early summer.

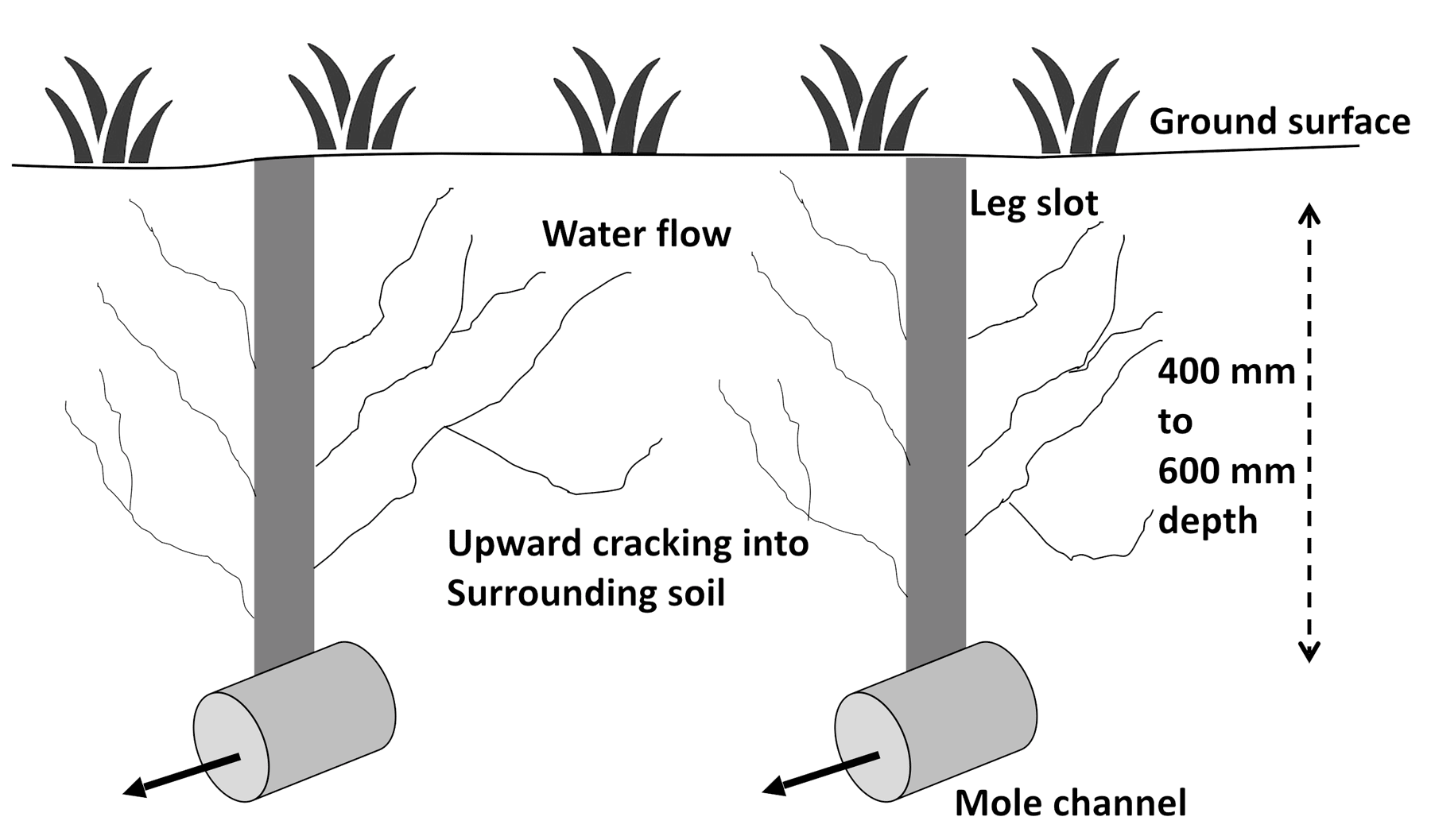

The action of the mole plough is to form a channel in the area of the profile with a specific clay content, yet produce upward cracking of the soil profile immediately above the mole channel. These cracks allow water flow to the mole channel.

The upper section of the soil profile needs to be dry enough to form cracks at the time of mole draining and the ground surface dry enough to allow traction. If too moist then the cracks can 'heal' over and reduce water intake. It is extremely preferable to have a warm drying period with no rain to allow the cracks to dry and the mole channel itself to harden.

Usually when the clay at mole draining depth has a moisture content of 20 to 25 per cent, conditions are satisfactory. Test the soil by kneading between the fingers. If a ribbon can be rolled out without it sticking to the fingers the moisture content is right.

Mole draining in autumn is not recommended, as the topsoil is wet and subsoil is too dry. The subsoil is difficult to mole and to dry out and it's difficult to achieve the desirable depth. Mole channels will tend to slough off and fail.

Length and gradient

The length of mole drains varies with the slope (gradient) of the ground (Table 1), surface evenness, soil textural changes in the profile and soil suitability. If mole channels are too long, the channels could remain wet at the lower end for too long, gradually softening over time and collapsing. If outfalls dictate long mole drains, then a collector pipe system is highly recommended.

Table 1: Recommended lengths and gradients for mole drains in pasture soils

| Soil profile | Surface gradient (%) | Mole length (m) |

|---|---|---|

| Clean | 0 to 1 | 40 to 50 |

| Clean | 1 to 2 | 50 to 60 |

| Clean | 3 to 5 | 80 to 100 |

| Stony | 0 to 1 | 30 to 40 |

| Stony | 1 to 2 | 40 to 50 |

Many mole drains have been installed at a length of 200m and some up to 400m have been pulled at Cooriemungle in south-west Victoria. These have performed satisfactorily for a number of years, but would survive much longer if the length was reduced (80 to 100m) because they would empty out quicker and are not likely to remain saturated.

Steeper gradients

Steeper gradients of greater than 3 per cent should enable relatively trouble-free moles because minor surface undulations won't cause blockages with negative gradients, and the risk from erosion is reduced. On steeper gradients, moles should cross the direction of the main slope to help intercept surface runoff and to avoid the possibility of channel scour and erosion.

Lower gradients

In most situations surface slopes are usually below 3 per cent and drains should run parallel to the slope fall.

The flatter the gradient, the more even the soil surface has to be and the use of collector pipe drains may be needed to achieve good results.

Depth

Optimum mole drain depth depends on soil type, and the conditions when moles are installed. Generally moles are pulled at 400 to 600mm depth. For most pasture situations a torpedo diameter of 65 to 75mm is recommended, although the channel diameter will be slightly less immediately after moling. A plug or expander attached to the rear of the torpedo will tend to maintain the channel size and smear the channel itself increasing its longevity.

Moles less than 400mm deep are liable to be damaged by tractors and animals during or immediately after rain. However, if mole drain depth is slightly less than 400mm, use a smaller diameter torpedo (35 to 45mm) to reduce ground heave during mole draining. Torpedoes of 100mm have been used but require substantially higher powered tractors and have not been proven to be an advantage over the smaller sized torpedoes.

A rule of thumb is that the expander to mole draining depth ratio is 1:7, that is, a 70mm diameter expander should have mole depth of approximately 490mm.

Very heavy soils and those with high contents of suitable clay down to moling depth may benefit from its first mole draining at a shallower depth due to tractor limitations. Also as the soil structure improves over time subsequent moles can often be pulled at deeper depth.

Spacing

Spacing is designed to promote an interlacing effect of the fracture pattern from the moling and so encourage maximum water flow opportunity. Spacing between moles is usually about 2m in dairy pastures. In less intensely grazed areas spacing may be up to 5m apart, but performance falls off markedly with wider spacing.

Outfall

The drain outfall or outlet is the most important part of the system. If this fails the whole system fails.

Mole drains can discharge to open drains, into interceptor drains filled with gravel, or preferably a collector pipe system. The latter two systems are more expensive, but protect the mole outlets and the only maintenance required is at the tile outlet (see Subsurface pipe drainage design and construction).

Open drain outlets should be fenced off from stock and kept clean so the outfall is above the drain water level. This prevents water backing up into the mole outlets, softening the clay channel and eventually causing them to collapse. Short lengths of plastic pipe inserted in the ends can protect them.

Another advantage of gravel filled interceptor drains is that moles can be pulled both ways, instead of the one way trip from open drains, speeding up the job.

Effective life

The effective life of a mole drain can be from hours (if done in the wrong conditions to 10 to 15 years (if done in the correct conditions). Moles in some soils have lasted longer. Even some soils that in theory shouldn't support moles are still operating after 5 years.

Other factors

- Improved drainage not only takes away surplus water but takes away some nutrients as well.

- Fertiliser should not be applied immediately before rain events when run-off is likely.

- Good management practices, such as not applying fertiliser within four days of predicted rain should reduce nutrient run-off to a minimum.

- Consider changing paddock layout to make mole draining easier.

- Water pipes often have to be re-laid.

- Drainage trenches can outfall to dams, so that more water can be harvested.

Water Act

The Water Act 1989 provides guidance for the management of waterways and swamps. Before considering draining a wet area, contact your local catchment management authority for advice and to check if you need a permit.