Types of subsurface drainage systems

There are several options available for draining excess subsurface water to a specific depth from the soil profile. The most suited drainage system is influenced by:

- soil type

- topography

- rainfall

- outfall type and location.

Drainage systems are expensive to install but, if they're well maintained, their benefits outweigh their initial cost.

Make sure you have surface drainage

Most wet soils problems are the result of waterlogged soil profiles, not just surface water.

Install surface drains to drain excess surface water off paddocks before installing your subsurface drains. This will reduce the load on the underground drainage system and allow you to install an effective subsurface system at a lower cost.

Benefits of a subsurface drainage system

Costing of drainage systems has shown that both increased pasture utilisation and extra pasture growth from drainage can be competitive with other feed sources. But to take advantage of this extra growth, more cows and farm improvements (including a feedpad) may be necessary.

Environmental sustainability benefits

Subsurface drainage provides many long-term sustainability intangible benefits, such as:

- improvement in soil health due to the increased aeration of the soil

- increased responses to fertiliser use

- reduced mineral imbalances in the soil and sometimes in the plants as well

- prevention or reduction of salinity (if in its early stages).

Improved animal production

Drained soils enable fodder conservation of silage and hay to occur several weeks earlier than on undrained soils. The resultant fodder has the potential to be of much higher quality, improving animal production.

Better retention in desirable plant species

Drainage, by reducing pugging and creating favourable soil environments, results in the retention of the improved pasture species, instead of promoting the influx of plants suited to waterlogged conditions such as rushes, fog grass, glyceria species and water couch.

Personal benefits to the farmer

Most importantly, reduced stress in managing stock and pastures during the wetter months of winter or spring has very large benefits for the farm operator.

Types of subsurface drainage systems

There are 4 main types of subsurface drainage systems:

- corrugated and PVC slotted subsurface pipes

- mole drainage (including mole drains, mole drains over collector pipe systems and gravel mole drains)

- interceptor drains

- ground water pumps.

Subsurface pipes

Subsurface pipes are best suited in deep permeable soils where their depth allows wider spacing and minimises cost. Subsurface pipes can also successfully drain heavy (clay), poorly drained soils but have to be installed so close together that they are uneconomic in extensive farmland systems.

Subsurface pipes can also be used in soils that might have an impeding layer (for example, clay) at some depth but, if the clay type and content is suitable, mole drains can be installed above these in a mole drainage over collector pipe system (skip to this section).

Correctly installed and maintained, these systems can last many years. Regular inspection of outfalls is necessary, as this is the weak link in all drainage systems.

PVC pipes replaced clay pipes

Subsurface pipe drainage was referred to as 'tile drainage' in the past due to the use of short clay pipes. Clay was expensive and difficult to lay and has now been replaced by slotted PVC or flexible corrugated plastic pipes of variable diameters.

How subsurface pipes are laid

Specifically, designed drainage trenchers, usually fitted with laser guidance equipment, dig the trench, lay the slotted pipe and place permeable backfill into the trench on top of the laid pipe. This backfill is delivered by trucks or trailers fitted with conveyor belts which feed the backfill into the hopper. The forward speed, hopper channel opening size and material size determine the depth and amount of material laid on top of the pipe.

Although trenches can be dug with a typical builder's type of trencher, producing a flat, even trench base of constant slope is very difficult. Laying pipes manually, without knocking soil into the trench before the pipe is laid, is also very difficult. The specific drainage machine uses lasers to maintain constant depth and fall regardless of ground surface conditions.

Backfilling the trenches

Backfill is a major cost of a drainage system but is crucial to the drain's effectiveness, so the quality and price of backfill should not be compromised.

In very permeable soils, very little backfill is needed, but in less permeable soils, or where moles are to be pulled through above a pipe, the backfill depth reaches to near the ground surface.

Mole drainage

Mole drainage can be classified as:

- mole drains

- mole drains over a collector pipe system

- gravel mole drains.

The suitability of each type will depend on the:

- clay content and type

- sand and stone in the profile

- gradient

- outfall location.

The action of the mole plough forms a mole channel in the area of the soil profile with a specific clay content. The plough also cracks the soil profile immediately above the mole channel, allowing water to flow into it.

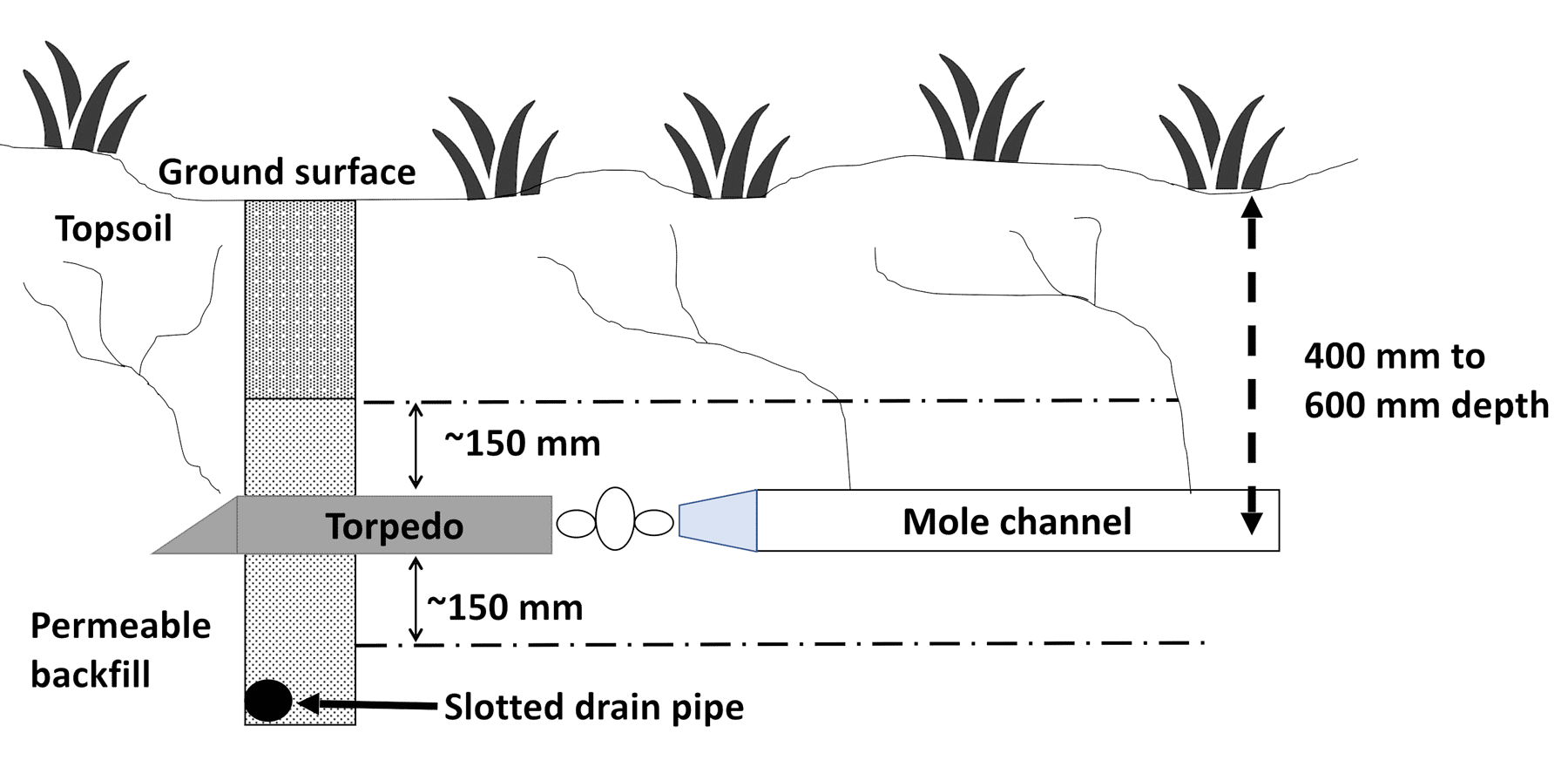

A mole plough is used to form mole drains. Simply, a mole plough contains a leg (or blade) with a torpedo (or foot) attached to its bottom. Sometimes a plug (or expander) with a slightly larger diameter is attached to the rear of the torpedo, to ensure the mole channel is left with the correct shape.

Mole drains

Mole drains are used in heavy soils where clay subsoil near moling depth (400mm to 600mm) prevents downward movement of ground water.

The success and longevity of mole drains is dependent on soils having a high clay content so that once a mole channel is formed, it will maintain the channel for many years. Mole drains are not suited to:

- soils with clay types that have dispersive or slaking characteristics

- permeable soils due to their high sand or loam contents.

Mole drains over collector pipe systems

This system is used in soils where it is not possible to form moles that reach the outfall. This includes the presence of stones, sandy pockets, uneven surfaces or excessive distances to the outfall.

In heavy soils where mole drains need to be very long (over 80m) before they reach an outfall, it can be very successful to install subsurface pipes at approximately 60m to 100m, over which mole drains are pulled. Washed sand or small diameter gravel is backfilled into the pipe trench to near the ground surface at installation.

Mole drains are then installed at or close to a right angle to the direction of the pipes. Excess ground water flows into and along the mole drains, then drains into the porous backfill above the pipes, and then is quickly removed to outfalls via the subsurface collector pipes.

Gravel mole drains

Gravel mole drains are best suited to soils and situations:

- where subsurface pipes are unsuitable

- where mole drains have a very short life span, or

- in slaking soils so the mole channel will maintain its shape at or soon after moling.

A gravel mole drain is an unlined channel or leg slot filled with small diameter gravel or washed sand.

Gravel mole drains are also expensive because of the:

- amount of backfill

- close spacing.

But they do offer an alternative in some 'difficult to drain' situations.

They might be useful in slaking and dispersive soil types, but get expert opinion if you're considering a gravel mole drain in these situations.

Interceptor drains

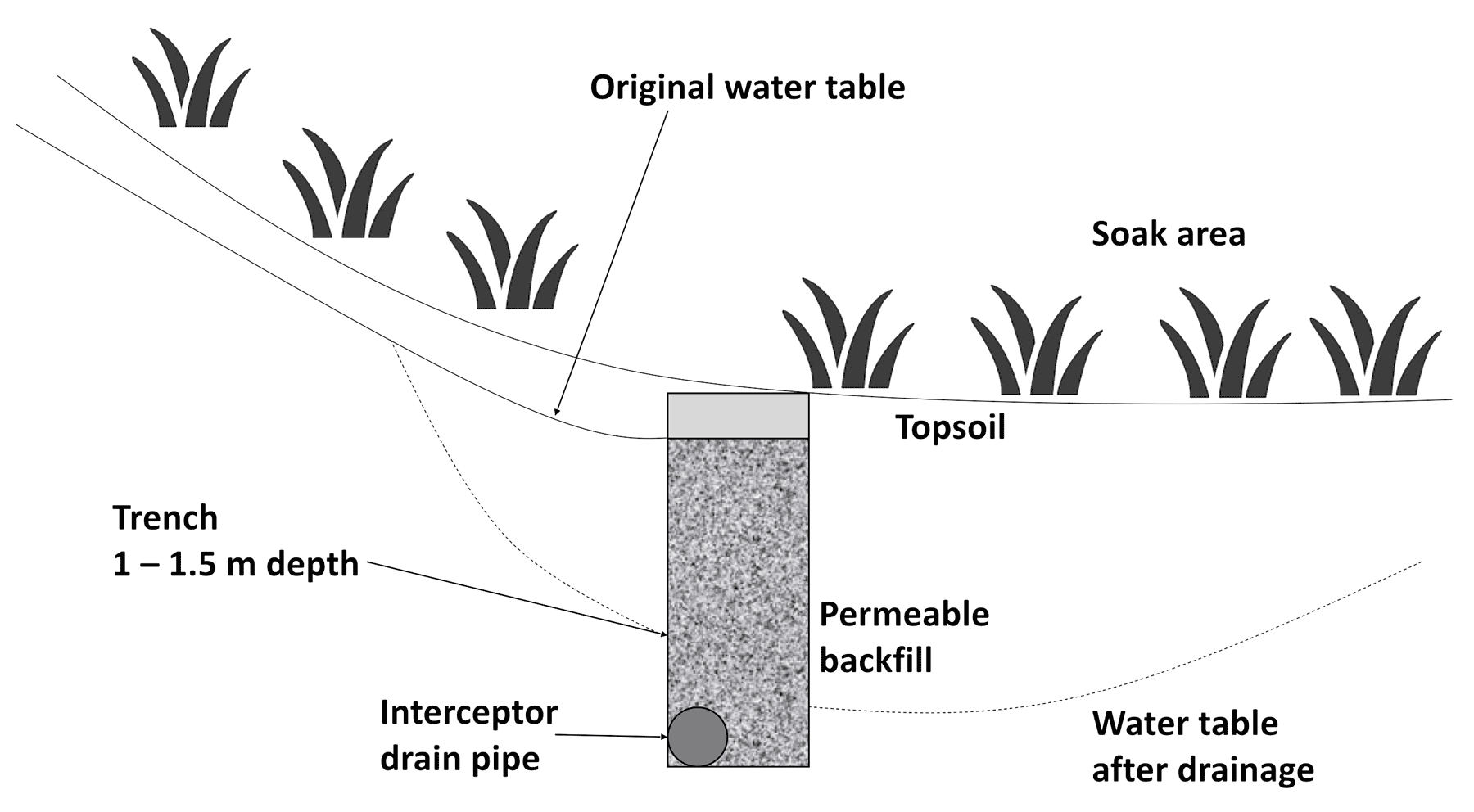

These drains are installed at the base of slopes at the change of gradient, usually where a steeper slope meets the flats to intercept the downhill flow of subsurface water. Often the soil type on the slope is more permeable than those of the flats and this forces the water to come to the surface, usually at the change of slope.

Interceptor drains can also be installed below springs and spring lines to intercept spring water. Grazing animals severely pug the areas around springs and damage is usually more concentrated down slope as the soil is very wet and has little structural strength. This affected area usually spreads unless fenced off.

Interceptor drains installed as close as possible to the spring and across its downhill flow can be effective in controlling the spread. Drainage reduces stock damage, or pugging, as the soil maintains its strength and structure.

Ground water pumps

These remove water from aquifers so, the water table will fall or be maintained at a suitable level below the ground surface.

The act of pumping causes a drawdown of ground water leading out from the pump's location — its effect will be much less at depth.

The extent of effect will depend on factors such as:

- aquifer depth

- soil type

- height of water table.

You must discuss with your regional rural water authority the cost, benefits, disadvantages, whether these pumps can be used and if you need a permit.

Choosing a drainage system

To decide which drainage system to install, you must first determine:

- the soil's characteristics

- its permeability (speed at which water can move through the soil)

- suitability for mole drainage (clay type and content).

Farmers and drainage contractors can often decide which subsurface drainage system to use based on some simple on-farm tests.

But if there is any indecision, have your soil tested or consult a subsurface drainage expert.

Water Act

The Water Act 1989 provides guidance for the management of waterways and swamps. Before considering draining a wet area, contact your local catchment management authority for advice and to check if you need a permit.