Subsurface pipe drainage design and construction

Wet soils are a common problem in the high rainfall districts of Victoria. In many cases the soil profile needs better drainage so pastures and crops can grow to their potential and to reduce stock damage by treading (pugging) and compaction.

Types of subsurface pipe drainage systems

There are 2 systems for removing subsurface water with subsurface pipe drainage. These are:

- subsurface pipes

- interceptor drains

See Types of subsurface drainage systems for more information.

Soil suitability for subsurface pipe drainage

Soil survey the proposed drainage area by auguring to at least a metre depth, noting soil type and its permeability. This is best done during winter so that soil permeability can be readily estimated by noting how long it takes for the surrounding water to fill an auger hole. The permeability or hydraulic conductivity is important in estimating the required drain spacing and depth and therefore the cost.

Generally, permeable soils that are sandy or loam based are suited to pipe drainage, but some well-structured clay loam soils can also be suitable.

See Which subsurface drainage system to use for practical tests to help determine the best drainage system for a particular soil type.

Design considerations

There are major design factors that must be considered when installing a system. There are much more technical aspects to some of these factors, so consult a contractor with experience and training in subsurface drainage.

Drain depth

Uniform permeable soils suit deeper the drain placement and wider drain spacing, which reduces cost. Pipe depths are typically a minimum of 700mm to 1200mm for drainage in soils growing pasture. Machines specifically constructed for trenching and pipe laying, are used solely by experienced contractors in Australia and can trench to a depth of about 2 metres.

In layered (duplex) soils, an impeding layer at some depth, such as a clay subsoil or coffee rock layer, causes the watertable to build up. This is referred to as a 'perched' watertable. These are common soil types in the south western district of Victoria and some areas in Gippsland. The impeding layer is situated at 300mm to 900mm depth. In these soil types, drains are usually installed just into the clay layer or some distance below the coffee rock layer and backfilled with a permeable material to well above the impeding layer.

The depth of the open main drain or creek (outfall) used to dispose of the water from the pipe system usually determines the depth of the tile drains. In some cases it will be better to use widely spaced deep pipes that drain to a sump. Although water must then be pumped to the outfall, this can be more economic than using closer spaced, shallower pipe drains.

Drain spacing

Drain spacing depends on the hydraulic conductivity of the soil, crop or pasture requirements and the drainage coefficient.

Hydraulic conductivity of the soil

Hydraulic conductivity is the speed at which the water moves through the soil. The more permeable the soil, the more rapid the water moves through that soil, and this allows much wider drain pipe spacing. The minimum hydraulic conductivity suitable for tile drains needs to be about 40mm to 60mm per hour. Conductivity rates lower than this requires pipe spacing to be too close, and is therefore uneconomic.

See Which subsurface drainage system to use for more information.

Crop or pasture requirements

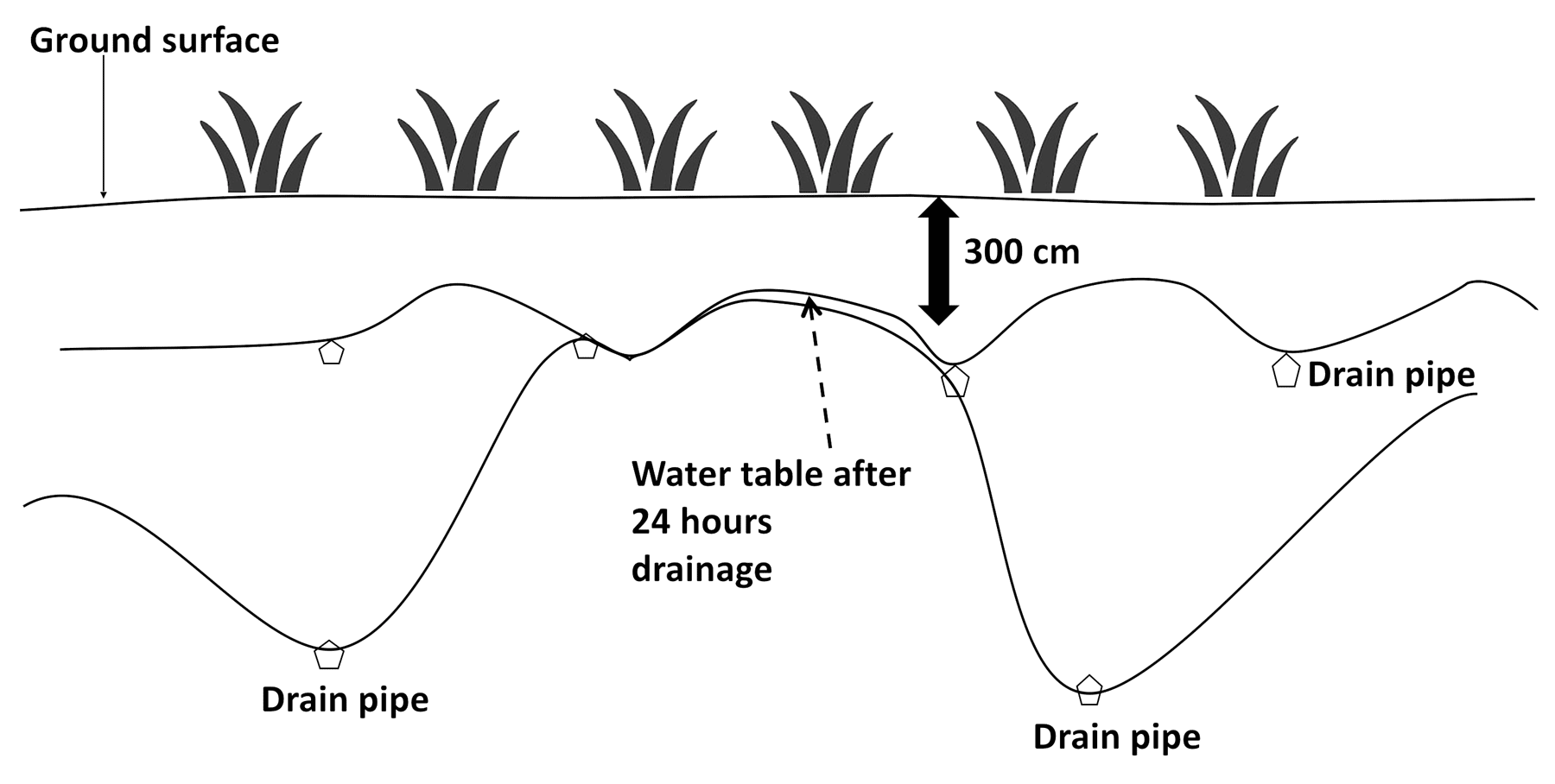

Orchards for example need to keep the watertable lower than crops or pastures do. For pasture, the watertable should be maintained at least 300mm below the surface, midway between drains, to enable grazing and tractor work on dairy farms without causing soil or pasture damage.

Design drainage rate

The design drainage rate is expressed as the amount of water the drain system has to remove over 24 hours to keep the watertable below 300mm (for pasture) midway between drains.

Different plants can tolerate waterlogging to different extents and farmers also require paddocks to be reusable soon after rainfall events. This dictates the removal rate of water from the soil profile after a rain event and is governed rainfall intensity (duration and amount). Soil type and pipe spacing and depth will influence this figure.

Limited trial work in the dairy areas of south west Victoria shows that 7mm to 10mm per day should be used as the drainage coefficient.

Pipe diameter

The pipe diameter depends on the volume of water to be removed per unit area per day and the gradient. Type of drain such as pipe only, compared to collector pipe system will also influence pipe diameter size. Tables are available from experts to help choose this information.

In pasture situations, most pipe laterals are slotted corrugated polythene pipes of 65mm to 80mm diameter. The main drains to outfalls are usually 150mm to 225mm diameter PVC pipes. But other pipe sizes and types are available so seek further advice from subsurface drainage contractors. Laterals are the smaller diameter pipes used to collect the water from the area to be drained. These then deliver the drainage water to larger pipes or main drains.

It is important to design the drainage system to allow for future extensions when your circumstances allow it — for example, if you purchase land purchase next door. Make sure the pipe diameter will be large enough to cope with the increased flow from new extensions.

Pipe length

The maximum length of main pipe lines is determined by

- the design drainage rate

- the area to be drained

- its capacity according to the gradient used

The steeper the gradient, the faster the drainage rate. Pipes should not be installed at excessive gradients, as fast-flowing water may create a suction effect on the surrounding soil and create erosion.

The length of the laterals depends on slope and length of the area to be drained, but a rough rule of thumb is that one length of small diameter pipe drains into the next diameter size up. Realistically, in most dairying areas, the smaller pipe diameter would drain into larger diameter main drains (100mm to 160mm) directly into outfalls.

Backfill

Permeable backfill should be placed around the pipe. This increases the permeability in the vicinity of the pipe, helping with a much faster removal of the water. It also acts as a filter to prevent fine sand and silt from entering the drains.

Most commonly used backfill are coarse washed sand, graded or pea gravels and blue rock screenings of small diameter. Because of its plentiful supply, scoria (30mm to 40mm diameter) is commonly used in the western districts of Victoria.

When drainage pipes are installed in the impermeable layer such as clay, the permeable backfill should extend well above the impermeable layer.

Collector pipe drains for mole drains should have screened gravel or scoria (12mm to 20mm diameter) to allow rapid water infiltration into the pipe. Sourcing good quality clean backfill close to the job will keep costs to a minimum.

Filter socks around slotted corrugated pipe are available for some situations to prevent very fine particles from entering the pipes. But there might be potential for the fine particles to block the filter itself so consult an expert to determine their suitability.

Gradient

Pipe gradient is determined by the:

- layout

- outlet depth

- drain depth

Minimum gradients can be as low as 0.1 per cent but the ground surface needs to be perfect with no irregularities. More often, 0.25 per cent should be the minimum gradient.

Laser graded trenches give more consistent grades and are absolutely necessary for situations with low gradients. Lateral pipes should cut across the slope to maximise water interception.

Costs

Each drainage system will vary in cost, depending on:

- the size of the area to be drained

- soil type (which determines pipe depth and therefore spacing)

- whether it is suited to mole drainage (with subsurface pipes or a combination)

- location of outfalls and proximity

- availability of suitable backfill

Current costs of a soil drained by mole drains over a pipe collector system are about $2000 to $2500 per hectare in soils where moles would be re-moled every 5 to 7 years. In a well maintained drainage system with appropriate pasture management, and depending on milk price, payback or breakeven price ranges from 3 to 5 years.

Get a detailed site investigation before installing pipe or mole drainage systems.

Other points to consider

Inspection pits (sediment traps)

Install these at specific pipe junctions. They assist in locating blockages in pipe lines and provide access for removing blockages.

Drain markers

Recording the location of existing pipes and their sizes are essential for future extensions, and to prevent existing drains from being dug up accidentally.

Drainage installations add value to the land and is a good selling point — as long as their location is known.

Draw up a farm plan and accurately mark drain locations on paper and distances from known permanent points on the ground, as after a couple of years there will be no sign where the drains are installed. An aerial photograph of the drained area immediately after installation is valuable.

Outlets

Drain outlets are the most important part of the system. If an outlet becomes blocked, the drainage system fails, becoming a huge needless expense. Outlets must be well marked (particularly when cleaning open drains) and protected from stock trampling.

Self-closing flaps will prevent vermin from making a home in the pipes and blocking the outlet.

Drainage water

The water may contain nutrients such as nitrogen and phosphorus and may have high salt levels if saline areas are drained.

Good management practices such as not applying fertiliser within 4 days of predicted rain should reduce nutrient runoff to a minimum. Well-drained soils are less likely to waste nitrogen fertiliser through denitrification and plants are able to access the nitrogen readily. Phosphorus can leach via drainage water but the total amounts lost are less than through surface runoff of saturated soils.

Some pockets of saline soils have the potential to be restored over time as rain water flushes out much of the salt via the drainage system. This will cause saline water to enter streams initially but eventually will actually improve the quality of the stream water as salt is leached from the soil profile.

Tree roots

Fine tree roots will very quickly gain entry through the slots so avoid laying slotted pipe where these may be a problem. Use un-slotted pipe for several metres to bypass tree roots.

Grazing management of drained paddocks

It is absolutely essential that, after heavy rain, drained paddocks are not grazed for at least 24 hours after the last rain. This allows the soil to drain and regain strength to withstand cattle and wheel traffic without damage.

A common fault by many farmers is to put cattle into drained paddocks during or soon after rain. This results in a compacted soil surface and reduces the drainage capacity of the soil.

Keep animals off drained soils for at least 24 to 48 hours to allow the drainage system to drain the excess moisture to about 30cm below the ground surface. This will also retain the structural strength of the soil. A waterlogged soil has greatly reduced strength so is easily pugged by hooves and damaged by machinery.

See Grazing management to reduce soil damage for more information.

Water Act

The Water Act 1989 provides guidance for the management of waterways and swamps. Before considering draining a wet area, contact your local catchment management authority for advice and to check if you need a permit.