Code of Accepted Farming Practice for the Welfare of Sheep (Victoria) (Revision Number 3)

Introduction

This code is intended as a guide for all people who handle and manage sheep. The aim of establishing this code is to achieve humane husbandry in all types of sheep enterprises. Assistance and specific advice on management and disease control in sheep should be obtained from qualified advisers, whose services are available through government and private agencies.

Sheep are kept in situations which vary from extensive grazing to close confinement and housing. Whatever the form of husbandry, owners, agents, managers and stockpersons have a moral responsibility and a clearly defined legal responsibility to care for the welfare of animals under their control.

The crucial importance of sound animal husbandry principles cannot be over-emphasised in the course of meeting the welfare requirements of animals. This code outlines sound sheep husbandry practices but is not prescriptive because good stock-handlers need to be flexible in their approach to caring for their animals.

Among the most important factors affecting welfare in a flock are the behaviour and attitude of the manager. Important skills of the competent manager and stockpersons include the ability to anticipate situations in which the welfare of the animals may be at risk and to recognise early signs of distress or ill-health in animals, so that appropriate preventive or early remedial action may be taken.

The basic requirements for the welfare of sheep are:

(a) a level of nutrition adequate to sustain good health and vigour;

(b) access to sufficient water of suitable quality to meet physiological needs;

(c) social contact with other sheep; but with sufficient space to stand, to lie down and stretch their limbs;

(d) protection from predation;

(e) protection from pain, injury and disease;

(f) protection from extremes of weather, which may be life threatening;

(g) provision of reasonable precautions against the effects of natural disasters, e.g. firebreaks and fodder storage;

(h) handling facilities which under normal usage do not cause injury and which minimise stress to the sheep.

1. Food and water

Minimum standard

- Sheep must be provided with access to a diet which is nutritionally adequate to maintain health and meet the appropriate physiological requirements for growth, pregnancy, lactation and to withstand cold exposure.

- Sheep must have access to water.

- Where provisions for health and vitality cannot be met sheep must be moved, agisted, sold or slaughtered on site.

Recommended practice

1.1 Food

In all systems of management, continual assessment should be made of the needs of the sheep in relation to the amount, quality and continuity of feed supply.

Sheep should be excluded, as far as possible, from toxic plants and other substances suspected of being deleterious to their health.

1.2 Water

Watering points should be of sufficient capacity and allow safe access. Regular assessment should be made of the quality and quantity of water supply.

Mechanical equipment controlling the delivery of water (including windmills and bores) should be inspected regularly and kept in good working order. Inspection should be more frequent in hot weather. Sheep should not be deprived of water for more than 36 hours. This period should be reduced in the event of hot weather.

The quality of water provided should be adequate to maintain sheep health. Drinking water which contains potentially toxic levels of salts, or other deleterious substances, should be monitored and managed to minimise deleterious effects.

Where sufficient good quality water to maintain health cannot be provided, the sheep should be moved to other areas where an adequate supply is available. Alternatively, they should be sold or humanely slaughtered on site.

2. Drought

Drought is defined as severe food and/or water shortage following prolonged periods of abnormally low rainfall. It is not a normal seasonal decline in the quantity and quality of food available.

Recommended practice

Owners and their advisers, should consider animal welfare as a major issue in their development of drought relief strategies.

Property strategies for drought management should be prepared well in advance and progressively implemented. Owners and advisers with limited or no previous experience of drought management should seek advice from qualified advisers. Where drought feeding is the preferred option, it should be started before paddock feed runs out.

Sheep being fed for survival should be observed carefully at feeding times. Weak animals may require segregation for special treatment.

Where minimal water and food requirements cannot be met, sheep should be agisted, sent for slaughter or humanely destroyed on the property. Drought affected sheep are highly susceptible to stress and require careful handling:

(a) if they are unable to rise and walk they should be humanely destroyed on site;

(b) if they go down after limited exercise, they are not fit to travel and should be humanely destroyed on the property;

(c) if they are still able to walk they should be agisted or sent directly to the nearest slaughtering plant; they should not be consigned through saleyards.

3. Protection from climatic extremes, natural disasters and predation

All reasonable precautions should be taken to minimise the effects of weather that produce either cold stress or heat stress in sheep. Freshly shorn sheep and newborn lambs are particularly susceptible. Windbreaks to reduce the effects of cold may be provided in the form of scrub or planted trees, long grass or artificial shelter.

Sheep should be attended to promptly in the event of fire, flood, injury or disease.

Where predation is known to occur, reasonable precautions should be taken.

4. Protection from disease

Sick, injured or diseased sheep should be given prompt and appropriate treatment or be humanely slaughtered (see Appendix 2). Advice should be sought from qualified advisers.

Appropriate preventive measures should be used for sheep for diseases that are common in a district or are likely to occur in a flock.

Medication, including vaccines, drenches and dips, should be administered in strict accordance with the manufacturer's instructions.

5. Feedlots

Feedlotting is a situation where sheep are kept in outdoor yards or housed in sheds and hand fed for various purposes, including live export, meat lamb production or fine wool production.

The design, location and construction of a feedlot should take account of topography, climate, age and size of animals to be kept there, space and feed requirements, and labour and management skills available. Adequate provision should be made for cleaning, drainage and waste disposal. All sheep should have adequate access to feeding and watering facilities, which should be maintained in good repair and clean condition.

Special requirements for selection, health, environment, floor space and food and water are included in Appendix 1: Special requirements for sheep in intensive systems.

6. Sheep handling facilities

Well-designed sheep handling facilities, and the ease with which animals flow through them, have important implications for the welfare of the sheep. When new sheep yards are to be constructed, or existing yards modified, expert advice should be sought.

Sheds and yards should be constructed and maintained to minimise the risk of injury and disease.

Passageways, races, entrances and exits should be designed to take advantage of the behaviour patterns of sheep.

The floors of sheds and yards should have surfaces that minimise the risk of injury and disease and allow sheep to stand and walk normally.

Where sheep are held in yards for extended periods, their requirements for food and water should be met.

7. Supervision

Owners and their advisers, including absentee owners and their advisers, should ensure that sheep are inspected sufficiently often to maintain them in sound and healthy condition. The frequency and thoroughness of inspection should be related to the likelihood of risk to the welfare of the sheep in relation to food, water, protection against natural disasters and likelihood of diseases, such as flystrike.

Housed sheep should be checked by an experienced stock-person at least once each day for signs of injury, changes in food and water intake, illness or distress.

Sheep grazing under more extensive conditions require variable supervision according to the density of stocking, availability of suitable feed, reliability of water supply, age, pregnancy status, climatic conditions and management practices.

8. Management practices

8.1 General

A large number of husbandry or management practices is required in any sheep farming enterprise. The consequences of not performing certain husbandry procedures may result in far more pain and distress to the animal than the procedure itself, when it is performed quickly and competently. Restraint used on sheep should be the minimum necessary to efficiently carry out the required procedures.

Practices that cause pain should be applied in such a way as to minimise pain and should not be carried out if practical alternatives can be used to achieve the same results.

Management procedures carried out on sheep should be performed by competent persons or under the direct supervision of an experienced operator.

Relevant hygienic precautions should be undertaken.

8.2 Handling and movement

There are times when sheep need to be handled for close inspection or shifted to another place. It is essential that the catcher handle the sheep gently to reduce stress to individual sheep and to other sheep nearby. If drafting facilities are not available, sheep may be caught, but not pulled, by one leg. If carrying is necessary, they should not be lifted by the wool. Sheep should be moved quietly through yards with the minimum forcing by dog or person. Care should be taken with gates to avoid injury to sheep. Precautions should be taken to prevent smothering of closely yarded sheep. Lambs and weaners are at particular risk.

The use of dogs and goading devices for handling sheep should be limited to the minimum needed to complete the procedures. Dogs should be effectively prevented from biting.

8.3 Shearing

It is normal practice to shear sheep annually. Additional limited shearing in the form of crutching, wigging and ringing may be required at other times of the year to reduce the risk of flystrike, and to minimise impairment of vision, and the incidence of stained wool.

Because shearing is stressful for sheep, managers should attempt to avoid undue handling and exposure to adverse weather. Sheep should be returned to food and water as soon as possible after shearing.

Where circumstances indicate, shearing cuts should be treated to prevent infection and flystrike.

A sheep’s fleece must not be allowed to grow to a length greater than twice the average annual growth for the breed of sheep or more than 250 mm (whichever is shorter).

8.4 Dipping

Dips or showers should be constructed, maintained and operated in a manner that minimises injury, disease and stress to sheep.

8.5 Paring of feet

Sheep which have poor hoof conformation, or are habitually on soft ground, may require regular foot paring.

Sheep affected with foot disease may need to have diseased tissue pared away by a sharp instrument. The paring should be kept to the minimum necessary to remove affected tissue and should not result in bleeding or severe lameness.

Paring may not be indicated in sheep with feet affected by foot abscess.

Control or eradication procedures should be adopted if evidence of foot rot occurs.

8.6 Horn trimming

The horns of rams, stags and some wethers may need to be cut back to avoid injury from an ingrowing horn or to other sheep and to allow free movement through handling races. The amount of horn removed should be limited to avoid damage to soft horn tissue and associated bleeding. Complete permanent dehorning should only be undertaken under general anaesthesia.

8.7 Lambing and orphan lambs

Ewe flocks lambing under grazing conditions should be disturbed as little as possible. However, the flocks should be under adequate surveillance to ensure that ewes having difficulty are given attention and to ensure that other problems, such as pregnancy toxaemia and predation, are not occurring.

Access to a sheltered paddock is recommended for lambing ewe flocks, if the risk of bad weather at lambing is high. Where orphan and stray lambs can be identified they should either be humanely killed or given attention. Fostering is a realistic option; especially on small farms. Some will need colostrum or colostrum substitutes, then milk on a regular basis. Warmth and shelter should be provided. Weak lambs with very little chance of survival should be destroyed humanely.

8.8 Identification

When it is necessary to mark sheep for permanent identification, it can be done by tattooing, tagging, notching or hole punching the ear. Electronic methods may also be acceptable. Consignment of sheep should comply with the Victorian legislation with regard to the National Livestock Information System.

In horned sheep, the horn may be hot branded provided care is taken to ensure that the branding does not predispose the animal to infection and does not burn sensitive tissue.

9. Husbandry procedures – surgical

Minimum standard

- The mulesing procedure must be performed in accordance with Appendix 3 'Mulesing procedure'.

- Sheep must not be mulesed after 12 months of age.

- Castration of rams over 6 months of age must be conducted under veterinary supervision using anaesthesia.

- Grinding, clipping or trimming of teeth must not be performed on sheep as a routine flock measure.

Recommended practice

9.1 General

Surgical procedures may cause pain and stress, which can be reduced with appropriate restraint and competent operators.

Strict attention should be paid to the suitability of the work area in which the operation is to be performed, the catching facilities and the type and amount of restraint. Temporary yards in well-grassed areas can be useful to minimise wound contamination with dirt, dust and faeces and to reduce the additional stress imposed by travelling.

Instruments should be adequately maintained and sterilised prior to use. Proper hygiene should be practised and animals given adequate aftercare. Stock managers should be trained in all surgical husbandry procedures or experienced operators should be employed.

When tetanus is known to be a risk, a vaccination program against tetanus should be considered to prevent the risk associated with surgical procedures.

9.2 Ear marking

Ear marking instruments should be sharp, with the cutting edges undamaged, so as to prevent tearing of the ear.

Ear tagging can cause some tearing of the ear if not conducted properly; careful technique will avoid this.

9.3 Tail docking

Tail docking may be undertaken where there is significant risk of faecal and urine contamination and/or flystrike, that leads to poor hygiene, health and welfare and/or failing to do so adds a significant cost to the farm system. It should be performed on lambs as early as management practices will allow, preferably between 2 and 12 weeks. Animals over 6 months require an anaesthetic.

Acceptable methods of tail docking, without anaesthesia, are: cutting with a sharp knife; applying rubber rings according to the manufacturer's recommendation; or using a gas flame heated scarring iron according to the manufacturer's recommendations.

The docked tail should be just long enough to cover the vulva in female sheep and be of similar length in the male.

9.4 Castration

Castration may be unnecessary if all lambs are to be marketed for slaughter prior to puberty, which generally occurs at an age of 3 to 6 months.

Where castration is required, it should be performed on lambs as early as management practices will allow, preferably before 12 weeks.

Acceptable methods of castrating male lambs without anaesthesia are by:

(a) cutting: the lamb should be properly restrained and the knife (cutting instrument) should be kept clean and sharp; good post-operative drainage of the wound is required;

(b) rubber rings applied according to the manufacturer's recommendation.

9.5 Mulesing procedure

The removal of wool bearing skin from part of the breech area of the sheep (mulesing) provides a high degree of life-time protection against flystrike in the breech area. See appendix 3 for the standard requirement for the procedure. Pain relief must be used when mulesing.

9.6 Pizzle dropping

Pizzle dropping is sometimes performed to reduce pizzle rot, wetting of the belly wool by urine and resultant flystrike in the region of the pizzle. The need for this operation should be considered according to the risk of pizzle rot and pizzle strike, and information should be sought on the correct procedure from the Department of Jobs, Precincts and Regions.

9.7 Teeth grinding/trimming

These procedures do not have any beneficial effect on health, well-being or productivity of the animals, but do have the potential to cause significant pain.

Corrective dental procedures on individual sheep may be undertaken to alleviate a specific dental problem if considered to be beneficial to its health and well-being.

10. Humane destruction

Effective and humane methods of destruction which cause a quick and painless death include either shooting with a firearm or by stunning with a captive-bolt pistol (captive bolt penetrating stunner) followed by bleeding out.

Minimum standard

- Sheep stunned with a captive-bolt pistol must be bled out immediately.

Recommended practice

10.1 Firearms

A suitable firearm for euthanasia is a .22 calibre rifle or .32 calibre humane killer pistol used at short range but not placed directly on the head. Disadvantages of the use of a firearm are hazards to human safety and the possibility of not being legal on public property.

10.2 Captive-bolt penetrating stunner (pistol)

An alternative to the firearm is a captive-bolt penetrating stunner which uses blank cartridges colour coded for the amount of power required for the species of animal being destroyed. The stunner is placed firmly against the skull before firing. The frontal approach as used for firearms is preferred although a poll approach is possible. The concussion stunner (non-penetrating) is not recommended.

The main advantage of the captive-bolt is the safety factor.

The positions and direction of the line of fire for either polled or horned sheep are shown in Appendix 2.

10.3 Blunt trauma

Lambs (but not adults) may be stunned by a heavy blow to the front of the forehead to render them unconscious. This should be followed immediately by bleeding out or another technique to ensure death without regaining consciousness.

Blunt trauma should only be used when there is no other recommended option for humane destruction and can only be used on lambs that are less than 24 hours old.

10.4 Bleeding out

Bleeding out should be conducted by a skilled person using a sharp knife on an unconscious animal. It is an acceptable method of emergency slaughter of individual animals on-farm.

The method is to lay the animal on its side, draw the head back and cut transversely to the spine just behind the jaw bone. The outcome should be cutting of both carotid arteries.

Appendix 1: Special requirements for sheep in intensive systems

Minimum standard

- Drinking equipment must be inspected daily (or more often in hot weather) to ensure it is operating correctly and that pipes, taps and ball valves are not blocked.

Recommended practice

1. Selection of sheep

Sheep should be carefully observed and those found to be unsuited to the system should be released to paddock grazing.

2. Preventative health management

Animals may need to be treated for internal and external parasites before entering an intensive system.

Vaccination with 6 in 1 vaccine against clostridial diseases and caseous lymphadentis is recommended.

3. Environmental requirements

The site should not be subject to flooding and should be away from fire hazards and relatively protected from adverse weather.

Sheep should not be kept in, or exposed to, any environment where the air is so contaminated with dust or noxious chemicals as to be detrimental to their welfare.

Sheep houses should be designed either for effective natural ventilation, or with mechanical ventilators to assist in the removal of excessive heat, moisture, carbon dioxide, dust, noxious gases and infectious organisms from the environment. Internal distribution of air is required in a manner appropriate to the location of the animals and the design of the building.

Adequate fire fighting equipment should be available to control a fire in any sheep housing shed, building or feedlot.

4. Floor space requirements

Overcrowding should be avoided. The suggested minimum space allowances for intensively managed sheep are:

Intensive indoor feedlots Space allowance (m2/head)

(a) Single pens

Type of sheep | Space |

|---|---|

Lamb | 0.6 |

Wether or dry ewe | 0.9 |

Ram, pregnant ewe or heavy wether | 1.0 |

Ewe with lamb(s) | 1.5 |

b) Group penned

Type of sheep | Space |

|---|---|

Less than 8 sheep | 0.9 |

9-15 sheep | 0.8 |

16-30 sheep | 0.6 |

31, or more | 0.5 |

Outdoor feedlots (shipping assembly)

Type of sheep | Space |

|---|---|

Lambs up to 41 kg | 1.0 |

Adult sheep | 1.3 |

Heavy wether (fat score 5) | 1.5 |

Ewe and lamb(s) | 1.8 |

5. Food

Sheep being introduced to an intensive feeding system, particularly high starch diets, should be given time to adjust both to the new dietary regime and the troughing. As a guide, conversion to a grain-based diet can be achieved by gradually replacing roughage over a period of 7–14 days. Where sheep are being introduced to a diet containing more than 60% cereal grain, the roughage should be gradually withdrawn over a minimum of 3 weeks.

Adequate trough space should be provided. Where sheep are being fed in groups on an ad lib basis, or where the trough contains food for up to 15 hours per day, a minimum of 2 cm of trough space per sheep is appropriate. Where smaller amounts of food are offered at set feeding times, up to 20 cm of trough space, to allow all sheep to stand and feed at the same time, is needed to reduce adverse feeding competition.

Close monitoring, and identification and treatment of shy feeders should remain one of the manager's major concerns throughout the feedlotting period and especially during the introduction of sheep to novel fodder.

6. Water

Fresh drinkable water in clean troughs should be available in sufficient quantities at all times. Sheep in feedlots may drink up to 6 litres per day during hot weather.

Where nipple drinkers or automatic feeders are used in group penning systems, one drinking nipple should be provided for every 15-30 sheep, with a minimum of two per pen. One watering bowl is required for each 60 sheep. Sheep may need to be trained for a few days to use nipple drinkers.

Where water troughing is used, at least 1.5 cm per sheep is recommended, provided inlet pipe sizes and water pressure are sufficient to keep water in the troughs under all circumstances. Poor water pressure or inlet pipes or thirsty sheep may be reasons for the trough length to be increased. A minimum trough length of 30 cm, plus 1.5 cm per sheep is recommended for mobs of up to 500.

Troughs should be equipped with drain plugs to assist cleaning. Where grain is fed, troughs should be cleaned at least daily.

When an intensive sheep husbandry enterprise is first established or a new water source is used, the water should be tested for minerals and organisms which may be toxic and advice obtained on its suitability for sheep. Information on water testing can be obtained from the local office of the Department of Jobs, Precincts and Regions.

Appendix 2: Euthanasia – use of firearm and captive bolt stunner

1. Using a firearm

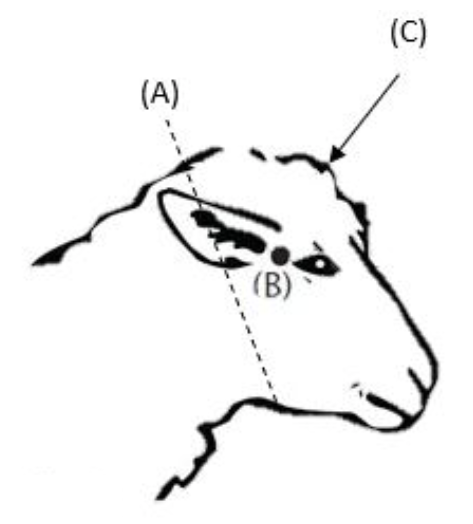

Hornless sheep and rams

Either:

- aim just behind the poll to slightly forward of the angle of the jaw of the sheep (A), or

- aim from the side of the bead at a point midway between the eye and the base of the ear (B), or

- aim at a point in the middle of the face just above the level of the eyes while aiming along the neck (C).

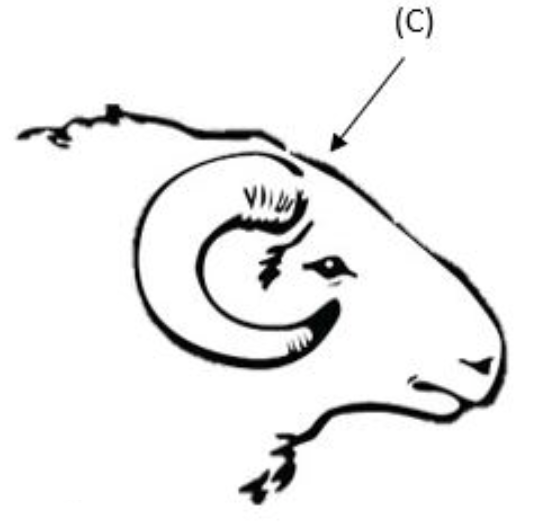

Horned sheep and rams

Aim at a point in the middle of the face just above the eye while aiming along the neck (C).

2. Using a captive bolt stunner

Hornless sheep and rams

Horned sheep and rams

Place captive bolt stunner firmly on top of head aiming from just behind the poll to slightly forward of the angle of the jaw of the sheep.

N.B. It should be noted that the individual anatomical differences between sheep may not be fully represented in these schematic diagrams

Appendix 3: Mulesing procedure

1. Introduction

1.1 Background

The mulesing procedure (mulesing) involves the removal of wool-bearing skin from the tail and breech area of sheep. It is intended for prevention of flystrike injury. The procedure is performed as a part of an integrated approach to flystrike management including crutching and shearing, good worm control, strategic use of chemicals, genetic selection and paddock grazing management. It provides a high degree of lifetime protection against flystrike in the breech area.

1.2 Values and principles underlying mulesing

Mulesing will be carried out only in circumstances in which it is clearly in the best interests of the long-term welfare of the animals.

- Any person conducting mulesing must be accredited to perform the procedure in compliance with an industry quality assurance management program.

- New technology and treatments, including use of pain relief, will be adopted promptly after approval, if shown to minimise risk to welfare, including pain, associated with the procedure.

1.3 Legislation

Legislation in States and Territories covering regulation of veterinary procedures and/or animal welfare must be complied with.

1.4 Indications for mulesing

Sheep producers should carefully consider all options for breech strike prevention in flocks before undertaking mulesing. Mulesing may not be necessary on properties in specific low risk regions, with improved selection and breeding for 'fly and worm resistance', where crutching is conducted 2-3 months before shearing, or where other strategies can effectively prevent breech flystrike.

Key indicators for use of mulesing are:

- The property on which the stock is farmed is regularly subject to a high risk of breech flystrike.

- The breed is Merino or Merino derivative.

- The sheep have significant wrinkle or wool cover in the breech area.

- The majority of the lambs to be mulesed are intended to be farmed as adult sheep.

- The sheep are likely to be sold and kept as adults in areas prone to breech flystrike.

2. Operator Competency

Persons carrying out the mulesing procedure must have appropriate competencies, demonstrated following a formal accreditation process or by other assessment by a Registered Training Organisation.

3. Selection of Sheep

3.1 Health and condition

A pre-operative evaluation of sheep must be conducted.

Animals in poor condition or showing signs of disease must not be mulesed. Poor health and condition increase the risk of post-operative complications and death.

3.2 Age

The recommended age for mulesing is 2 to 12 weeks. Mulesing should be done in conjunction with lamb marking to minimise stress and handling. Only in exceptional circumstances, such as proclaimed drought or other exceptional conditions that prevent mulesing to be conducted at the recommended age, can lambs can be mulesed over 12 weeks of age. Mulesing of sheep over 6 months must be done with anaesthesia.

Additional monitoring should be done for sheep mulesed over 12 weeks of age and any sheep showing signs of infection or ill health should be treated promptly.

4. Preparation

4.1 Weather

Choose a fine, mild day.

Weather extremes should be avoided. Cold weather places an additional stress on lambs. Wet or dusty conditions increase the risk of wound contamination. Windy conditions may interfere with mothering up. Excessively hot conditions can increase bleeding and stress on lambs.

4.2 Time of day

Marking and mulesing should be done at a time which minimises the separation of lambs and ewes and allows mothering up to occur as quickly as possible.

Mulesing should be done when fl y activity is expected to be minimal.

4.3. Stock handling and facilities

Do not drive or stress lambs before mulesing. Let them settle and cool down after mustering and before starting. This will reduce blood loss and aid recovery.

Mulesing must be carried out on clean, well-grassed areas in paddocks that have sufficient feed and water for at least four weeks after mulesing to avoid the need to move mulesed sheep. Wet, muddy, manure laden or dry dusty areas must be avoided to reduce the risk of wound contamination.

Use of temporary or portable yards is recommended to ensure:

- The procedure can be carried out in an appropriate paddock.

- The sheep do not have to be moved far immediately after the procedure.

- The sheep can drift away slowly on release from the yards.

5. Equipment

5.1 Cradles

A mulesing cradle must be designed to:

- Hold the lamb securely in a symmetrical position.

- Position the hind legs close enough together so that folds of skin can easily be picked up.

- Expose the rear end of the lamb in a more horizontal than vertical position.

- Release the lamb on its feet to prevent contact of the wound with the ground to prevent contamination.

- Enable effective cleaning and disinfection.

Cradles must be maintained in good working order and be operated with minimal risk of injury to the operator or lamb, especially when loading and unloading.

5.2 Shears

Shears used for mulesing must be properly prepared and maintained. Shears may be either bent or straight and must be sharpened and set correctly to allow straight-edged cuts to be made efficiently.

To allow sufficient time for used shears to be cleaned, disinfected and sharpened between batches of lambs, at least three pairs of shears should be used.

5.3 Equipment NOT to be used

The following equipment must NOT be used:

- 'Dunking' containers must not be used for insecticide application to the animal because the solution becomes contaminated with blood, faeces and urine, which can then be transferred to subsequent animals.

- Paint brushes must not be used for application of insecticide dressings because they gather and transfer blood, faeces and urine to subsequent animals.

6. Hygiene

- Shears must be thoroughly cleaned and disinfected before initial use and each time they are changed for sharpening.

- Dirty shears must be washed to remove all blood, wool or faeces to permit the disinfectant to work effectively.

- Most disinfectants also have a detergent effect, which will assist with washing. However, if disinfectant is used in the washing process, this must NOT be regarded as having disinfected the equipment.

- At least two containers should be used, one for cleaning dirty shears before immersing them in disinfectant and one for disinfecting shears that have been cleaned.

- Containers must not be chipped, dirty or of a design that harbours bacteria.

- Registered surgical disinfectant must be used, according to label instructions.

- The disinfectant must be changed frequently (as soon as the solution is discoloured) because it will quickly become contaminated with blood and possibly faeces, urine and soil.

- It is not recommended to dip shears in disinfectant between lambs unless the disinfectant is changed prior to it becoming contaminated. If shears become visibly contaminated they should be cleaned and then dipped in clean disinfectant solution.

7. Pain relief

A pain relief product must be used on all sheep that are mulesed. The product must be one that is registered for use on sheep by the Australian Pesticides and Veterinary Medicines Authority (APVMA).

Consult your veterinarian to determine which product, or combination of products, is the best for your circumstances.

8. Flystrike protection after mulesing

Mulesing should be done when fly activity is expected to be minimal. In rare cases, despite use of insecticides, mulesing wounds may still become struck.

The following measures should reduce the risk of flystrike and the need to use chemicals following mulesing:

- avoid mulesing when conditions are ideal for flies.

- sharp, clean equipment must be used for mulesing.

- encourage rapid wound healing, by removing the minimum amount of wool bearing skin to achieve the desired bare area.

- ensure lambs are not disturbed, mustered or handled for at least 4 weeks after mulesing to assist wound healing. However, voluntary movement to adjacent areas is acceptable to allow access to fresh feed.

- if an insecticide wound dressing is necessary, spray equipment should be used to apply a registered product, according to label instructions, immediately after completion of the procedure and before releasing the lamb from the cradle. Dry powder dressings should not be used as they may delay healing.

9. Technique

The approved mulesing technique is described in detail in the National Mulesing Accreditation Program.

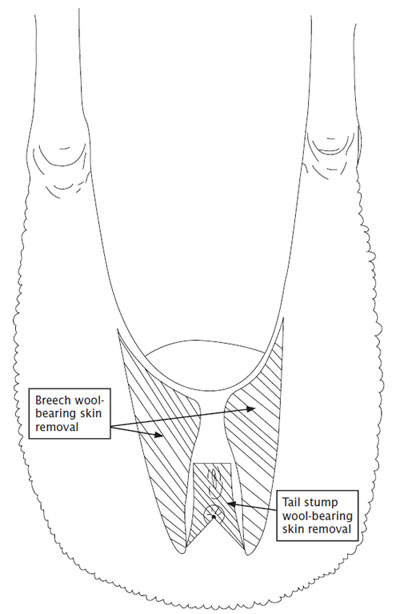

The principles are:

- Allow the sheep to cool down before operating in order to minimise blood loss.

- The inside edges of the cuts should closely follow the line of the natural bare area. It is critical that no bare skin is removed.

- A thin strip (approximately 2mm) of wool bearing skin should be left between the mules and natural bare area.

- The breech cuts on either side of the vulva, or similar length in the male, must not join each other. A strip of skin from below the vulva to the udder must remain intact, or similar length in the male.

- The minimum number of cuts should be used to achieve the desired result and this will depend on the conformation of the sheep.

- The size of the wound should be the minimum to achieve sufficient flystrike protection.

- The 'V' of the woolled skin left on top of the tail must be within the range of one third to two thirds of the docked tail length.

- The tail of the lamb should be removed as described in section 9.3 of this Code but without the use of rubber rings.

- The cuts should not have any jagged edges. Cuts with jagged edges become a focus of potential infection and flystrike and may delay healing of the mulesing wound.

- Both sides must be symmetrical to avoid distortion of the vulva or tail.

- Only wool bearing skin is removed during the mulesing process. No other tissues such as selvage (muscle fascia – membrane overlying the muscle), muscle, or other underlying tissue are to be removed or cut. Cutting or removing these tissues will cause:

- Delayed healing

- More pain

- More scarring

- Possible distortion of tissues during healing

- Possible distortion of the function of tissues after healing.

Figure 1 mulesing procedure incisions for breech area

10 Post-mulesing management

Upon release from the cradle, the lamb should be landed on its feet to avoid contact of the wound with the ground to prevent contamination. Operators should continually evaluate their technique by checking wound symmetry and position as lambs are released.

10.1 Mothering Up

- After release, the lambs should be allowed to immediately 'mother up' to the ewes. It is recommended that ewes be held in a small holding paddock or temporary fenced yard next to where lambs are released after the procedure. Where the paddock lambs are released into is large, a temporary fence to keep ewes from wandering off can assist with mothering up.

10.2 Movement

- If it is unavoidable, ewes and lambs may be moved IMMEDIATELY after completing the operation. They should only be moved quietly over short distances taking less than half an hour.

- Lambs should then not be moved for four weeks after mulesing or until mulesing wounds are healed. However, voluntary movement to adjacent areas is acceptable to allow access to fresh feed.

10.3 Monitoring

- Stock should be observed without disturbance at least every 3 days during the healing process. More frequent inspections should occur where the threat of flystrike or other risks are likely.

- Lambs which are abandoned and/or unable to stand up and walk should be given immediate treatment or humanely destroyed whilst minimising disturbance to the remainder of the mob.