Code of Practice for the Welfare of animals at saleyards

This code of practice is intended as a guide to all stock handlers involved in the management of animals of various species at saleyards, including truck drivers, stockmen, livestock agency staff, stock inspectors, producers, saleyard managers and their staff.

The aim of establishing this Code is to minimise stress to all livestock by encouraging efficient and considerate treatment and handling. The Code covers aspects of unloading, pre- and post-sale handling, the provision of feed, water, shelter and general care of livestock at saleyards. Recommendations are also given for the care, treatment and humane emergency slaughter of sick, injured or 'downer' animals.

Procedures at saleyards may subject animals to a variety of stressful situations such as:

- yarding and handling

- restricted access to food and/or water

- exposure to extremes of weather

- unfamiliar surroundings, noises and sensation

- mixing with unfamiliar animals

- exposure to infectious diseases

Each species of animal needs to be handled differently and this Code describes some methods of handling that can assist in minimising stress.

It is recommended that animals travelling long distances be given sufficient time after arrival at the saleyard to feed, water and rest in accord with any pre-sale curfew restrictions. Allowing for any rest period required, animals should be held in saleyards for as short a period as possible.

1. General

The people managing and handling the animals must be sensitive to the basic needs of the individual animal and be aware of any travel stress that livestock at saleyards may be suffering. The skills for managing and handling animals include the ability to:

- work so that stress to animals is minimised

- use the natural behaviour of animals

- recognise early signs of stress and disease and to initiate prompt and appropriate preventative or remedial action

Good stockpersons are flexible in their approach to livestock management and handling and adapt to the needs of differing animals and circumstances.

Saleyards should be sited away from fire- and flood-prone areas and, as far as is practical, away from residential areas. They should be constructed and maintained in accordance with appropriate animal welfare and animal behavioural considerations. The responsibility for the maintenance and functioning of the saleyards should be clearly defined and publicised.

Prior advice of intention to consign stock, especially large numbers of stock, to saleyards is desirable to avoid overstocking of facilities.

Diseased, sick, injured or drought-weakened stock should not be consigned to, or processed through, saleyards.

2. Management personnel

Managers, superintendents or saleyard supervisors

Managers, superintendents or saleyard supervisors of saleyard complexes have overall responsibility for the welfare, care and handling of animals at saleyards. They are in charge of the day-to-day activities at the saleyards, either directly through the supervision of the actions of saleyard staff or indirectly through the livestock agents and contract stockhandlers. They should ensure that high standards are maintained in relation to:

- stock handling by all handlers at the saleyards

- appointment of staff competent in stockmanship

- training and supervision of staff

- feeding, watering and regular inspection of all animals when not in the care of owners or the owners' appointed agents

- obtaining prompt veterinary attention for diseased, sick or injured animals and arranging removal of injured animals and/or carcasses from the yards. Subject to firearm legislation, a rifle and/or captive-bolt pistol should be kept at the yards and be readily accessible for use for emergency slaughter

- appointment of stockmen responsible for loading, unloading and receiving of animals when the owner or the owner's appointed agent is not present

- allocation of appropriate holding, drafting, selling and post-sale pens

- maintenance of cleanliness and upkeep of the yard structures, building and facilities for the handling and housing of animals

Stockmen and/or animal attendants

The importance of competent stockmanship to the welfare of livestock cannot be overemphasised. The ability to recognise the early signs of distress and injury in animals is an important skill that enables prompt remedial action to be taken. Competent persons are required to exhibit patience, commonsense and responsibility in dealing with animals. Inexperienced persons should not be given tasks requiring particular skills or be required to work alone at any time when animals are being handled. Inexperienced staff should be given training in stock handling by competent and skilled staff. Such training should emphasise the behavioural characteristics of stock.

Under no circumstances should cruelty or ill-treatment of animals be tolerated.

3. Stock handling facilities

Ramp design and construction

Loading and handling facilities should be constructed so that they do not cause injury to animals. Where possible, the vehicular approach to the ramp should have a slight fall backwards to enable vehicles to be rolled into position gently. A line should be painted on the road surface to assist this approach.

Ramps should be illuminated from directly above to encourage better livestock movement, and for the safety of operators.

The internal walls of ramps should be sheeted, smooth and high enough so that animals cannot be disturbed by activities outside the ramp and will not injure themselves. Safety exits must be provided for operator use on cattle ramps. In addition, a non-protruding step rail should be provided to allow handlers to quickly exit the loading ramp.

Provision of a walkway for use by handlers on the outside of the ramp will facilitate stock movement and is essential on sheeted ramps. Access into the ramp and hence the vehicle from this walkway is also desirable to facilitate the closure of transport pens.

The walkway should be constructed of a non-slip material, have adequate handrails and kick boards and comply with the Australian Standard AS 1657:2018 'Fixed platforms, walkways, stairways and ladders — Design, construction and installation'.

Where ramps are adjustable, appropriate safety locking devices must be installed with clear instructions as to how they are to be used. These safety locking devices should be automatic in operation and have vertical increments of no more than 100mm.

Design considerations for species

Cattle and horses

Loading ramps should be wide enough to accommodate the hip width of mature animals. Excessive width may obstruct loading. An internal width of 760mm will be sufficient for most animals.

Ramps should be constructed appropriate to the species of stock and transports used. A flat platform at the top of the ramp should be level with the deck being unloaded and should be not less than 1.5 metres in length to assist loading and unloading. Suggested ramp heights are 1100mm to 1200mm from the ground for single deck or bottom deck, and 2800mm to 2900mm for top deck.

A slope of not more than 1 in 3 (about 20 degrees) is recommended for permanently installed ramps. The surface should be made of non-slip material with either cross cleats, 40mm to 50mm wide spaced at 300mm centres or, if concrete, a suitable cross-grooved pattern of steps to provide good footing when the ramp is wet. Livestock prefer to walk up steps rather than inclines. Recommended dimensions are 450mm treads and 100mm rises.

Overhead bars on ramps used for horses should be of sufficient height to prevent head injuries to rearing horses.

Pigs lambs, sheep, goats and calves

Ramps should be 900mm wide for all species except pigs, where 900mm to 1000mm is recommended to accommodate 2 pigs side by side and prevent jamming.

On fixed ramps, a flat area of platform at least 1 metre in length is recommended at truck height. Ramp steps with 250mm of treads and 50mm rises or cross-cleats 25mm wide and high at 200mm centres are recommended.

Holding paddocks and yards

Sufficient yards should be provided to avoid mixing different consignments of animals and fences should be secure to prevent their escape.

Projections likely to cause injury should be completely eliminated from all fences and gates. Fences should be high enough to prevent animals mixing or escaping. Gates should be wide enough to allow easy flow of animals without injury. A minimum width of 2500mm per gate is recommended.

An added safeguard to the welfare of stock held overnight is provided by dog-proof perimeter fencing. This is especially desirable for saleyards that are used for sheep or calves and situated near residential areas.

The provision of shade or cooling systems in hot climates and shelter from excessive cold for animals in holding facilities is desirable, recognising practical and economic limitations. Animals should be protected from extremes of weather.

Laneways and races

Laneways and fences should be sheeted where appropriate to avoid animals being disturbed by outside activities and to direct them along desired pathways. Properly designed curved sheeted races and forcing yards should be provided to facilitate the movement of animals.

It is undesirable for animals to be kept on concrete for prolonged periods. Concrete floors should have non-slip surfaces. Walkways for handlers and buyers separate to laneways for livestock are recommended, especially for large cattle-selling centres. Overhead walkways should be constructed to minimise the casting of shadows in livestock laneways.

Facilities and procedures should aim to minimise dust and eliminate boggy conditions.

Drains should be constructed to avoid injury to animals and to ensure efficient drainage from pens and holding areas and sited so as not to impede the movement of animals.

A veterinary inspection crush should be available for individual treatment when necessary.

Drafting

Drafting facilities that utilise the natural tendency of livestock to follow one another are recommended. For drafting cattle, 360-degree overhead operated facilities are preferred.

Lighting should be installed to avoid, as far as possible, shadows and dark areas across laneways and in drafting yards, particularly where animals are drafted at night. Animals need to see a clear path in front of them. Noise levels should be kept to a minimum.

When drafting livestock, operators should allow time for the animals to see where they are required to move and to give them room to move. Rushing animals only confuses them, and causes further stress, hindering the drafting operation.

Selling pens and buyers pens

Selling pens should allow for adequate viewing of stock by buyers. For cattle, new yards should allow for entry and exit gates from the pen to the cattle laneway, the gates being at least 2400mm in length and hinged to enable the gate to contact the other side of the lane. The height of panelling should be 1650mm for cattle. Generally the yard space required for livestock is that area that allows the stock to move freely around the pen and buyers to make an assessment.

The density of cattle in selling pens should allow for all cattle to have access to water.

Appropriate stocking densities for sheep should take into account the age, condition, wool length and size of the sheep.

Lower densities should be used where there are calves or lambs at foot.

Different classes of stock should be maintained separately as far as practical. Individual pens should be provided for the sale of bulls.

Watering facilities

Watering facilities should be provided in all receival yards and in any other yards or pens where animals may be held for more than 12 hours. Facilities should be provided to ensure that the following groups have access to cool, clean drinking water:

- all animals that have been travelling for more than 12 hours or deprived of water for a total period of more than 12 hours

- all animals held overnight

- all animals held in yards for more than 12 hours or lesser periods during hot weather

Troughs should be constructed and located to minimise injury to animals and minimise fouling with faeces. They should be capable of being easily cleaned and should be cleaned before each sale.

Automatic equipment should be checked frequently to ensure that it is functioning. Water pressure should be adequate to keep water containers full at all times.

Water troughs or bowls can be situated on the boundary of 2 pens.

Small troughs are preferable to large troughs as they are more hygienic, provide fresher water and are less likely to injure or hinder stock. Troughs should not be less than 600mm long, 300mm wide and 300mm in depth, and there should be enough troughs to allow 15mm of trough length per sheep and 30mm per cattle beast in receival, delivery and spelling yards.

Nipple drinkers and bowls should not be used as the sole source of water for cattle or sheep.

In earth yards, concrete aprons or gravel 1000mm wide should be provided around the watering points.

Feeding at saleyards

As a general rule animals should not be without food for more than 24 hours, including the time spent travelling and yarding. For immature animals the intervals between feeds should be considerably shorter.

The owner or agent is responsible for the feeding of livestock where this is necessary. Arrangements for feeding and water should be made with the person in charge of the saleyard in the absence of the owner and agent.

Bobby Calves

Bobby calves must not be held longer than 10 hours without being fed an appropriate liquid food.

Maintenance

Yards, gates and equipment should be maintained in good repair. Boggy areas should be filled with gravel if more permanent means of eliminating such conditions cannot be undertaken.

Truck washing facilities

Truck cleaning facilities (sufficient water under high pressure and suitable drainage) should be provided at all saleyards.

4. Loading and unloading

Welfare advantages of efficient handling

Animals should be unloaded as soon as practicable after arrival and in a manner that does not cause them injury. If they are allowed to walk quietly off the rail wagon or vehicle, injuries can be avoided.

Trucks should be correctly aligned with the ramp so that no gaps exist. Flaps or adjustable bumper rails should be used to avoid such gaps. Proper alignment with the race will ensure the smooth movement of animals and minimise the risk of injury and bruising.

Lighting should be provided for unloading at night. Lighting should be carefully positioned to give even light over ramps, races, yards and pens to avoid glare and to minimise shadows.

Because livestock tend to follow each other, sufficient area should be provided in forcing/receival yards during loading and unloading to allow them to move easily towards the target area.

A minimum forcing yard area of 30 square metres is recommended for large stock for loading a 12m semitrailer. A minimum forcing yard of 20 square metres is recommended for sheep. A forcing yard with one straight and/or sheeted side can help to facilitate loading.

Methods of assisting the handling of animals

Electric prods should be powered only by battery or hand dynamo and must not be more powerful than necessary. Their use must be restricted to the absolute minimum. The continual prodding of animals that have little or no room to move must not occur.

'Flappers' (a length of cane with a short strap of leather or canvas approximately 300mm in length attached) or 'metallic rattles', used sparingly, will encourage movement of animals. Sticks, lengths of heavy plastic, metal piping or heavy leather belts must not be used on stock.

Well-trained dogs can assist in loading, unloading and moving sheep. In confined areas they cause stress to sheep. Their use should be strictly limited to that necessary to complete the task. The use of dogs in lieu of appropriate yard design is not supported. Dogs must be effectively prevented from biting. Dogs must also be supervised at all times and be secured when not working.

Dogs must not be used to work pigs.

The unloading area should be restricted to authorised persons only. Unloading should be supervised by experienced stockmen.

Separation of animals during holding

Animals of different species should not be mixed, in particular calves or sheep with pigs. Within species, unless they arrived in one consignment from a single point of origin, the following categories should be kept separated:

- females with suckling offspring

- females known to be in advanced pregnancy

- mature entire males

- unfamiliar groups of pigs

It is also desirable, whenever possible, to hold separately:

- hornless and horned animals

- animals of significantly different sizes

Unloading of injured animals

Healthy animals should be unloaded first, as quietly as possible, to minimise further injury to injured animals. Injured animals should be attended to without delay.

Severely injured animals should be humanely killed without delay. If a veterinarian is unavailable, this should be done by, or at the direction of, the person in charge of the saleyards. It is unacceptable to delay killing severely injured animals for any length of time. If in the judgement of a veterinarian or stock inspector an injury is minor and is not causing undue pain and/or distress, affected animals should be promptly segregated and treated.

Animals requiring emergency slaughter should be shot or stunned and bled without moving them further than necessary to effect euthanasia. It may be necessary to carry out emergency slaughter on the transport vehicle.

The practice of winching, or dragging by any means, living injured animals from transport vehicles is unacceptable. Unloading injured and moribund animals from trucks by tying them to a fixed object, such as a tree or ramp, and driving the transport vehicle away is equally condemned. Live animals should not be lifted by the head, horns, wool or legs.

The place for humane slaughter should be safe for the operator and persons nearby and should be able to be cleaned afterwards.

5. Special considerations of species

Pigs

Pigs are more susceptible to heat stress and sunburn than other livestock. They should not be exposed to long periods of direct sunlight or extremes of temperature. Panting is a sign of heat stress. Spray facilities should be provided for cooling animals.

Pigs should be unloaded immediately on arrival at the saleyard unless facilities exist for vehicles to park in a roofed area with spray facilities. All procedures involving pigs (including holding and selling) should be conducted under a roofed area.

Pig holding pens should have no-slip floors impervious to moisture, and should have walls constructed so that pigs cannot fight with unfamiliar pigs in adjoining pens.

Cool, drinkable water should be provided at all times in holding pens. If provided by drinkers, allocation, design and flow rates should be such that water requirements of different classes of pig are met with undue effort, taking into account normal expected wastage rates. If water troughs are provided they should be firmly fixed and the sides high enough to prevent fouling with faeces. Water troughs should have a minimum of 100mm of trough length per pig. Where drinking bowls are used, at least one bowl should be provided for each 15 pigs. They should be regularly inspected and cleaned. Holding pens should have not less than 0.47m2 per pig, or space as required by state legislation.

Unweaned calves (bobby calves)

It is desirable to present bobby calves for sale that are bright, alert, strong, vigorous, able to stand on their own, capable of being transported and at least 4 days old. Calves that fail to meet these requirements must not be taken to saleyards. In bobby calves, the junction of the umbilical cord and skin must be dry and the cord shrivelled.

Vehicles containing calves must be unloaded as quickly as possible on arrival at saleyards.

The minimum recommended liveweight for bobby calves being sold is 23kg at the point of sale. Obviously immature, dopey and listless calves should not be presented for sale.

Sick or injured calves are to be given appropriate treatment or be humanely destroyed. They are not to be presented for sale or transport or slaughter.

Handling of calves should be carried out in a manner that will avoid injury or unnecessary suffering. Calves are not to be kicked, beaten, pulled, thrown or 'dumped' or prodded with any sharp instrument. The use of electrical goading devices or dogs when handling, driving, drafting, weighing, loading or unloading is not an acceptable practice.

It is desirable to provide a roofed area to protect calves from the sun. A sealed no-slip floor must also be provided. This floor must be hosed clean after each sale to minimise the risk of spread of disease.

Calves are highly susceptible to scours and dehydration. They must be removed from saleyards as quickly as possible following sale. Bobby calves must not be held longer than 10 hours without being fed an appropriate liquid food.

Unweaned lambs and kids

Lambs or kids under 1 month of age must be accompanied by their dams when taken to saleyards.

Animals in advanced pregnancy

While it is not recommended that animals in advanced pregnancy be consigned to or sold through saleyards, it is recognised that this at times unavoidably occurs. Such animals should be given special treatment in regard to handling, holding times and provision of feed and water.

6. Industrial disputes at abattoirs

Once management is advised of an impending dispute at abattoirs supplied by the saleyard, efforts should be made to limit further consignments of stock to that saleyard. It should be the responsibility of the person in charge of the saleyard to contact stock agents and media (radio and television) so that farmers are informed of the need to keep their stock on the farms until the dispute is resolved.

Where stock are already at the saleyard, the person in charge should endeavour to arrange an 'emergency kill' with a slaughtering establishment. If this is not possible, adequate feed and water must be provided for all livestock held at the yard during the dispute.

If arrangements cannot be made for the emergency slaughter of bobby calves at a registered establishment, they should be humanely killed at the yard without delay if an alternative satisfactory method of care cannot be arranged for them.

7. Humane destruction of stock

Previous sections of this code have drawn attention to those circumstances in which stock may need to be humanely destroyed — for example, following serious illness or injury.

While this task is aesthetically unpleasant to most people, the method of slaughter should be effective and cause sudden and painless death for the animal. It is equally important that the animal be handled quietly beforehand to ensure it is not unnecessarily distressed or alarmed. The following recommended methods are those that are considered the most suitable at saleyards.

Use of firearms

The most efficient and widely available method of humanely destroying livestock is a gunshot to the brain from close range. There may, however, be legal restrictions on the use of firearms in public places. Under those circumstances, assistance should be sought from veterinary practitioners, the RSPCA, the Police or Agriculture Victoria Inspectors of Stock.

The following aspects of firearms safety should be borne in mind:

- a.22 calibre rifle or a .32 calibre humane killer pistol is adequate for humane destruction of most animals

- any use of firearms is potentially hazardous

- persons other than the marksman and a handler for the animal should be cleared from the area or should stand well behind the marksman

- never fire while the animal is moving its head — wait patiently for a quiet interval before firing

- to provide maximum impact and the least possibility of misdirection, the range should be as short as circumstances permit

- while the humane killer pistol and captive-bolt pistol are designed to be pressed firmly on the head before being discharged, it is not safe to do this with a standard rifle or pistol

Use of the captive-bolt pistol

An alternative to the firearm is a captive-bolt pistol (captive-bolt penetrating stunner), which is safer since a blank cartridge is used. The operator does not have to be a marksman as the instrument's muzzle is firmly pressed against the skull before firing. It must, however, be assumed that the animal has only been stunned and a follow-up method of ensuring death, such as bleeding out, is required.

Blank cartridges for the captive-bolt pistol are colour-coded according to the amount of charge they contain. For best results, the manufacturer's recommendations should be followed on the most appropriate blank cartridge for different farm animals. Regular maintenance of the captive-bolt pistol is essential for efficient stunning.

Special requirements of stock

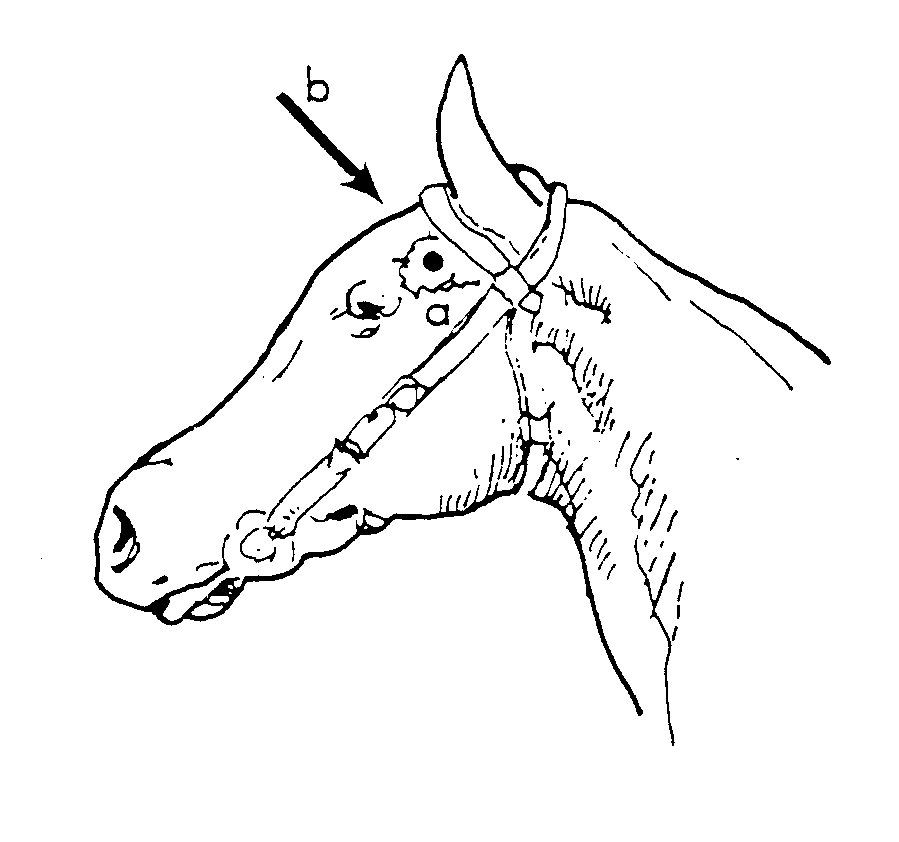

Horses

A head collar or bridle should be put on the animal to enable it to be quietly restrained by an assistant who must stand out of the line of fire. Restless animals should be blindfolded.

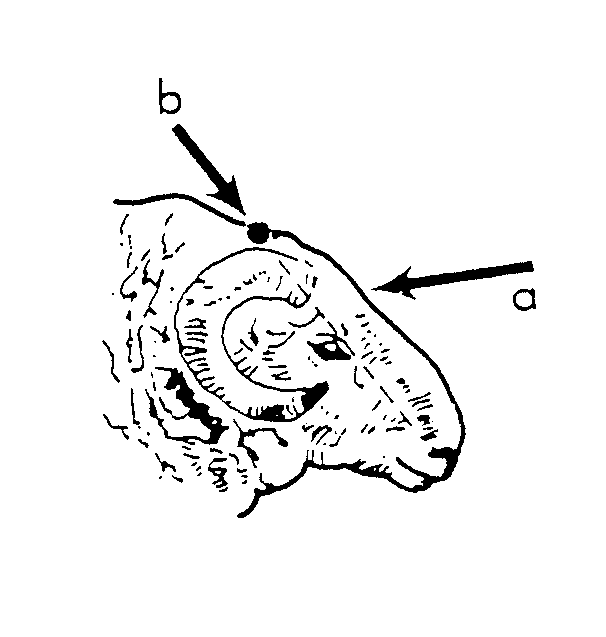

- Frontal method: the captive-bolt pistol or firearm should be directed at the point of intersection of diagonal lines taken from the base of each ear to the opposite eye. The bullet should be directed horizontally to ensure the brain is damaged (see Figure 1).

- Temporal method — only suitable for firearms: the horse is shot from the side so that the bullet enters the skull midway between the eye and the base of the ear on the same side of the head. The bullet should be directed horizontally.

Only a suitably designed captive-bolt pistol should be used to destroy horses. The manufacturer's instructions must be followed for best results. Major blood vessels of the neck should be severed as soon as possible, taking care to avoid injury caused by the animal's involuntary movements.

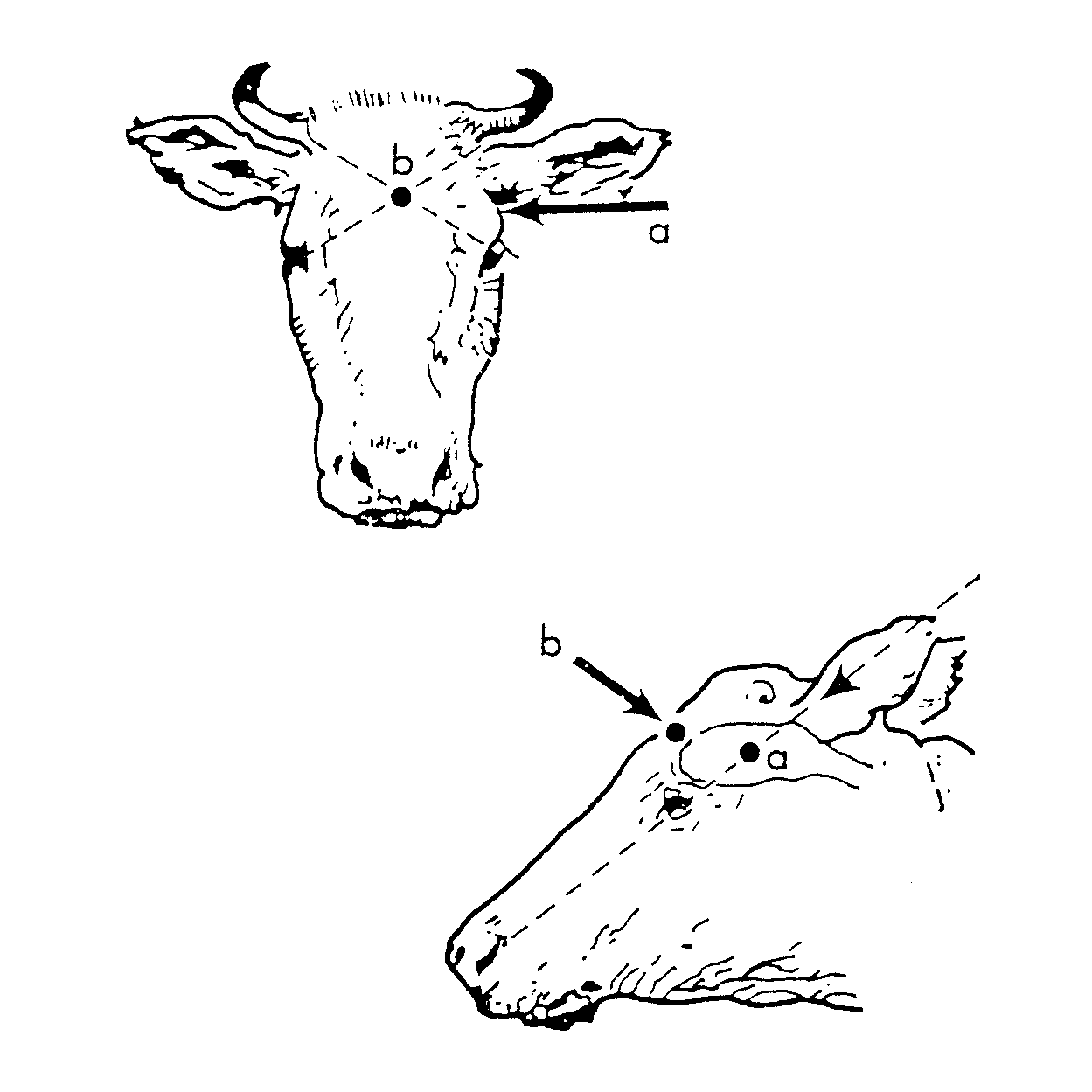

Cattle

- Frontal method: the captive-bolt pistol or firearm should be directed at the point of intersection of lines taken from the base of each ear to the opposite eye (see Figure 2).

- Temporal method — only suitable for firearms: the animal is shot from the side so that the bullet enters the skull midway between the eye and the base of the ear on the same side of the head. The bullet should be directed horizontally.

When the animal has been stunned using a captive-bolt pistol, it should be bled out as soon as it collapses by severing the major vessels of the neck. To avoid injury due to the animal's involuntary leg movements, the operator should stand behind the neck.

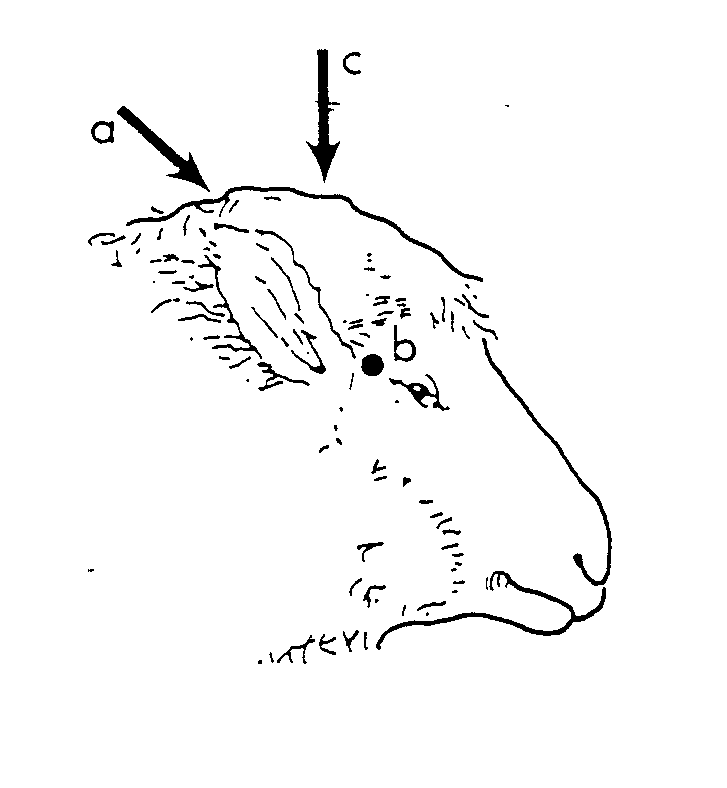

Sheep

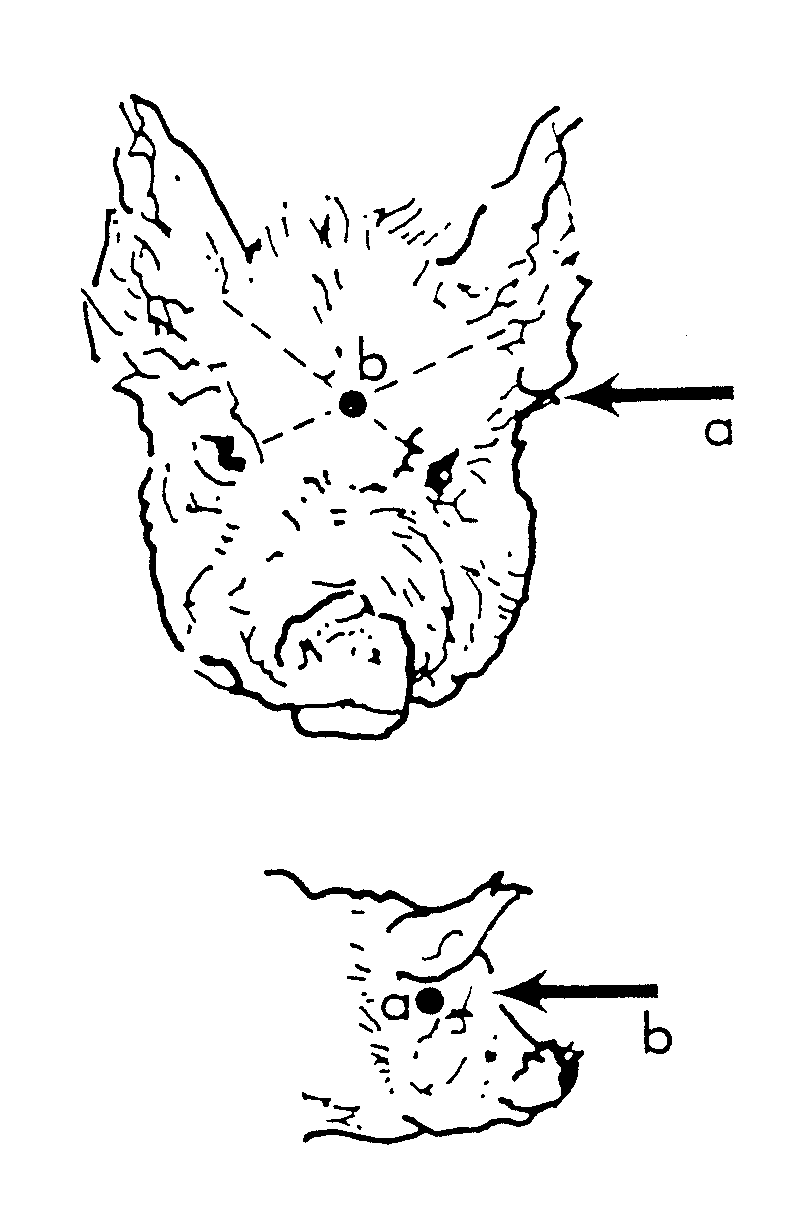

Hornless sheep and rams:

- The firearm or captive-bolt pistol should be placed just behind the poll and aimed in the direction of the animal's muzzle (position 'a' Figure 3).

or

- The firearm should be aimed from the side of the head at a point midway between the eye and the base of the ear (position 'b' Figure 3).

or

- The captive-bolt pistol should be placed on top of the head and fired vertically downwards (position 'c' Figure 3).

Horned sheep and rams:

- The firearm is aimed at a point in the middle of the face just above the level of the eyes and aimed along the neck (position 'a' Figure 4).

or

- The captive-bolt pistol should be placed behind the poll and aimed in the direction of the animal's muzzle (position 'b' Figure 4).

Pigs

- Frontal method: the captive-bolt pistol or firearrn should be directed at a point about midway across the forehead and (for adult pigs) about 2cm above the level of the eyes (Figure 5). When using a firearm, aim horizontally into the skull.

- Temporal method: only suitable for firearms. The pig is shot from the side of the head so that the bullet enters the skull at a point midway between the eye and the base of the ear on the same side of the head. The bullet should be directed horizontally into the skull. This method is preferred for adult pigs due to the heavier bone structure of the front of the skull.

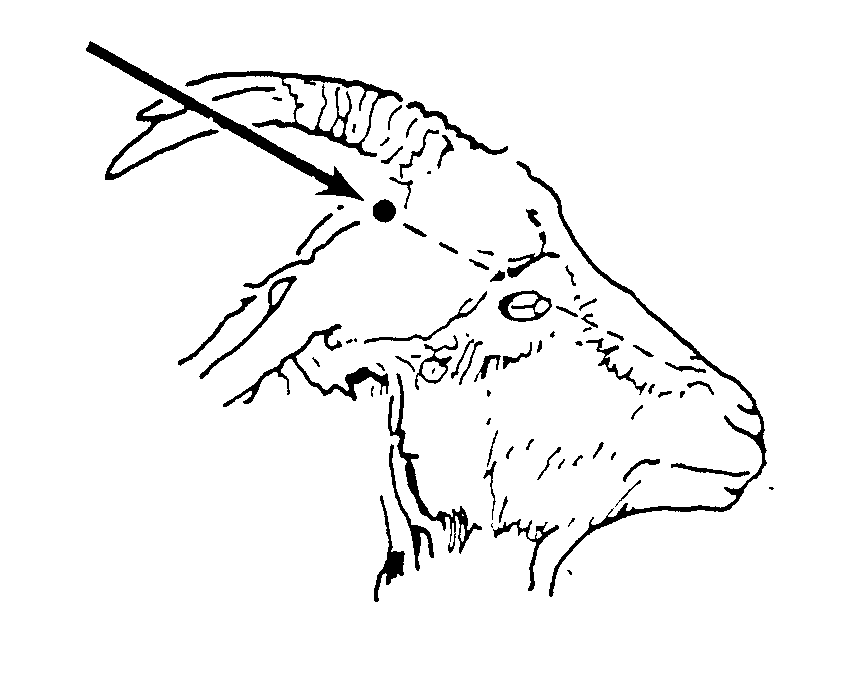

Goats

Using either a captive-bolt pistol or firearm, direct the instrument to the skull behind the horns as shown by the point of the arrow in Figure 6. Aim the firearm in line with animal's mouth, and take care that no one is in the line of fire.

Kids may also be shot from the front as for cattle. However, this method is not suitable for mature goats as the brain is located well back in the skull compared to other livestock.