Managing chemical residues in crops and produce

Conventional agricultural systems in Australia use a wide range of agricultural chemicals to boost the yield and quality of produce and to control weeds, insect pests and disease. While recognising the important role these chemicals play, growers should be mindful that consumers are becoming increasingly concerned with the level of chemical residues in produce.

The main concern is when chemical residues are detected at unacceptable levels (i.e., above the Maximum Residue Limit (MRL)) as this provides an indicator that chemicals may not have been used in accordance with Good Agricultural Practice (GAP). There is also a risk that an unacceptable residue may impact on human health, market access and could have serious repercussions for trade markets, both domestic and international.

Managing chemical residues is essential. Growers are responsible for ensuring that chemicals are used correctly to minimise any chance of unacceptable chemical residues occurring.

Follow the label directions

Labels provide detailed information about what crops/produce a chemical can be used on, what pest it controls, application rates, withholding periods (WHPs) and MRLs. Using a chemical product according to the label directions minimises the risk of unacceptable chemicals residues occurring. This is because the use has been tested and is warranted by the manufacturer. Any variation from the label directions is considered an ‘off-label’ use and should be avoided where possible.

Off-label use of chemicals

Off-label use refers to situations when a chemical is used in a manner that is not specified on the chemical’s product label. Examples of off-label use include when a chemical is used to control a different pest or to protect a different host (crop/animal), at a different rate, or in a different manner to that listed on the label.

In Victoria, it is legal to use chemicals other than ‘restricted use’ chemicals (i.e., agricultural chemical products that are Schedule 7 Poisons (Dangerous Poisons or contain atrazine, metham sodium or ester formulations of MCPA, 2,4-D, 2,4-DB or triclopyr)) off-label providing that:

- the maximum label rate is not exceeded

- the label frequency of application is not exceeded

- any specific label statements prohibiting the use are complied with (e.g., DO NOT statements).

The main issue with using a chemical off-label, relates to the ability to manage residues in treated produce. When a chemical is used off-label, how it interacts with the crop being treated, and how long it will take before the residue reaches an acceptable level is unknown.

Chemical users should thoroughly consider their options before using a chemical off-label, and be willing to accept total responsibility for:

- efficacy

- residues in the environment

- occupational health and safety issues

- residues in produce.

Factors affecting Chemical residues in crops and produce

Chemical residues will generally persist in crops/produce for a period of time following chemical application. The rate at which a chemical accumulates and degrades in a plant can be difficult to predict and depends on a range of factors, including:

- the rate and frequency used

- the formulation and properties of the active consistent in the chemical product

- adjuvants added to the chemical product or/at application

- equipment used

- climatic conditions during and after application

- crop characteristics and growth stage

- crop growth after application

- the rate of chemical breakdown in plants, soil or water and resulting products from the breakdown.

Spray drift or accidental spraying can also cause unwanted chemical residues.

Analytical residue testing and withholding periods

Residue testing data is used to determine WHP statements placed on chemical product labels. A WHP is the minimum period of time that must elapse between the last application of an AgVet chemical product, and the ‘use’ or consumption of the agricultural produce to which the chemical was applied. The WHP on a label is designed to ensure that food and fibre derived from chemically treated and crops complies with domestic market MRL’s.

Tolerances for chemical residue levels permissible in domestically consumed food products are set by set by the Australian Pesticides and Veterinary Medicines Authority (APVMA) and Food Standards Australia New Zealand (FSANZ). Crops or produce with residue levels below the MRL are considered to meet GAP and are acceptable for sale and consumption.

There is a greater likelihood that produce treated off-label will contain unacceptable residues, which is why off-label chemical users are particularly at risk, as any residual effect from using the chemical off-label may be unknown. Given that there may be no MRL established, any detection could seriously impact on trade markets, both domestic and international.

There are significant penalties that may be imposed on growers that are found to be selling produce that is contaminated with unacceptable chemical residues.

Managing Off-label use of chemicals

While Agriculture Victoria encourages the use of chemicals in accordance with label directions, it is recognised that there are some situations where a chemical can be used off-label.

Managing residues when using a chemical off-label is a complex task, and growers should seek professional advice whenever possible.

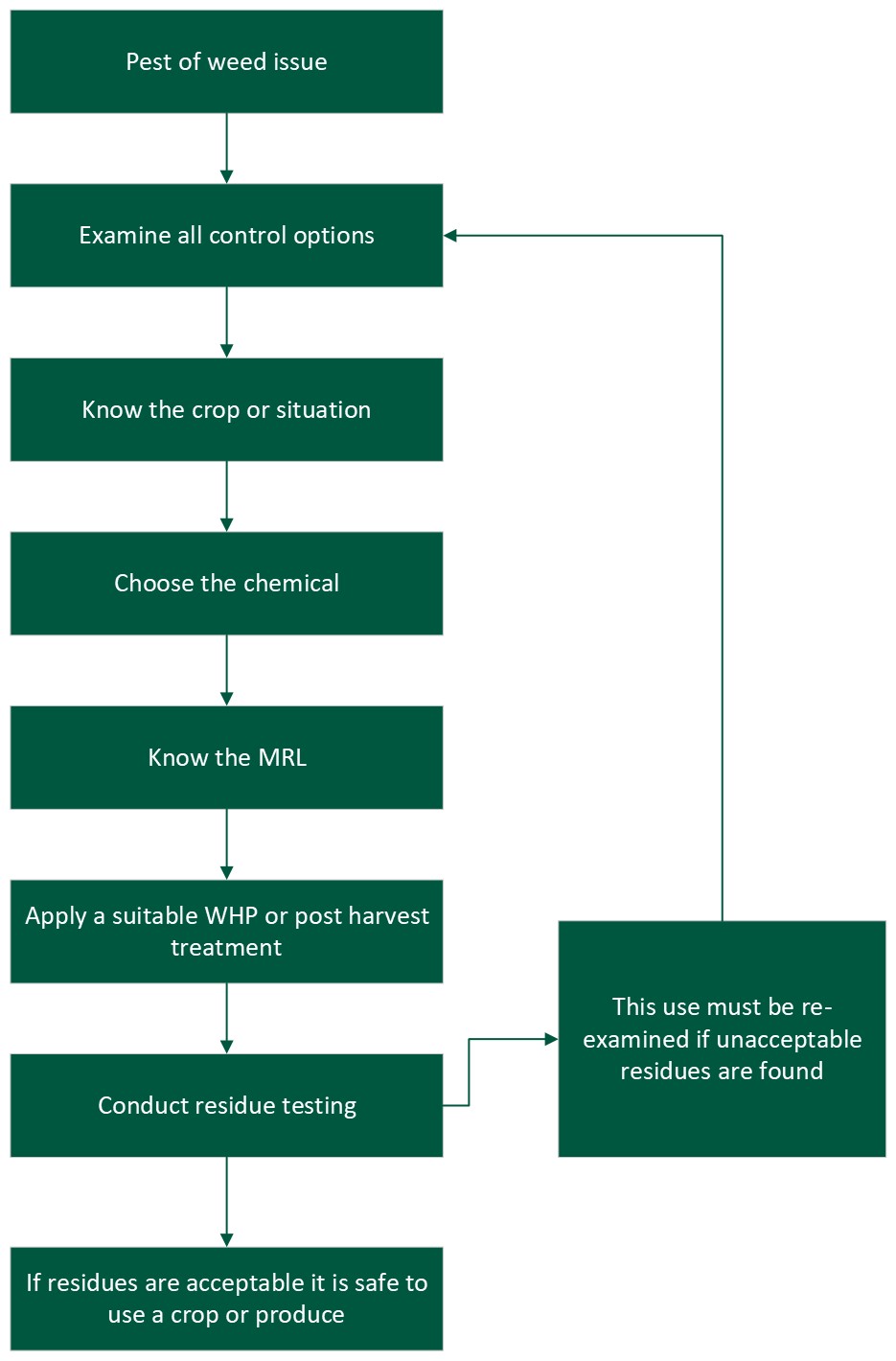

While each situation may be different, there are steps that growers can take to manage residue risks.

Step 1: Examine all control options

Examine physical, cultural, biological control options and chemicals registered for use in the situation. Chemical use may be avoidable or minimised if an alternative pest control method can be used. Off-label chemical use should be only used as a last resort.

Step 2: Know the crop and situation

Knowing the crop and situation may not be as simple as it sounds. The type and growth stage of the crop can have a major effect on the uptake and degradation of a chemical.

For example, a fast, actively growing crop is more likely to degrade or disperse chemical residues within the plant.

It should not be assumed that it is safe to use a chemical according to label directions when it is used off-label in a situation that appears to be similar to the registered use, as there can be unforeseen outcomes from such a use.

Case Study 1 – Strawberry growers

Several strawberry growers used an off-label chemical to control Rutherglen bug.

The chemical was registered to control cluster caterpillar and cutworm in strawberries in Queensland and the Northern Territory and there is a MRL established for strawberries.

The growers followed the label directions for strawberries when Rutherglen bugs were problematic. In some cases, multiple applications were conducted. As a result, residues were detected in the strawberries at levels up to three times the MRL.

Climatic differences between the states and increased frequency of application were likely to have contributed to the unacceptable residue.

Step 3: Choose the chemical

Choosing an effective and safe chemical can be difficult. Growers are encouraged to seek professional advice when selecting a chemical to use. A professional can advise on issues such as the effectiveness and risks of using a particular chemical, appropriate application rates and methods. Where possible, choose a chemical that has the crop or situation listed on the label.

Care should also be taken when tank mixing with other chemicals, adjuvants or fertilisers.

Step 4: Know the intended market’s Maximum Residue Limits (MRLs)

There is a risk that the market may not have an established MRL, particularly with respect to off-label use and export markets. In this situation, any detection of the chemical residue may be considered unacceptable.

Many countries have established their own MRLs for a range of produce to suit their requirements, many of which differ to those in Australia. Some countries choose to adopt the international MRLs set by the Codex Alimentarius Commission. There are also instances where there is no MRL established.

Growers supplying export markets must be aware of the differing MRL requirements for the countries they supply and factor them into their chemical use. The absence of a MRL may be a good reason to select a different chemical.

Case Study 2 – Exported wheat

Australian wheat was treated with fenitrothion whilst it was stored in Australia. The chemical treatment was a registered label use with an established MRL of 10mg/kg.

The wheat was then exported to India, where Indian authorities detected fenitrothion residues above the Indian MRL of 0.02mg/kg. This detection caused a disruption to trade.

Step 5: Apply a suitable withholding period (WHP) and/or post-harvest treatment

After applying a chemical, growers should allow a suitable WHP before selling or using the treated crop or produce. In some circumstances, a post-harvest wash may assist to reduce surface residues however, this won’t alter the need to adhere to any WHP’s that apply.

Step 6: Testing for residues

Many chemical users are aware that unacceptable chemical residues can present problems. Unfortunately, this is often overlooked because the problem cannot be physically seen. Often, a problem isn’t found until it is detected through a governmental testing program or by the produce buyer.

To manage unacceptable residues risks (particularly when using chemicals off-label), growers should send a sample of the treated crop to a National Association of Testing Authorities (NATA) accredited laboratory for chemical testing. The laboratory should be asked to test for all chemicals that are used where the crop or produce was grown, including neighbouring crops.

Growers should consider annual testing as a risk assessment tool to verify that unacceptable residues are not the product of any off-label chemical use.

If unacceptable residues are detected, the chemical user must re-examine their options and chemical use practices.

Summary

Growers must carefully consider the consequences of all chemical use practices, especially when chemicals are used off-label.

Produce is traceable to the producer, who can be held accountable for any unacceptable residues present. Growers must therefore take care to ensure any residues present are acceptable to the market they are selling to. If not, their actions could have serious repercussions.

More resources

The websites below may assist you in managing chemical residues in crops and produce.

Australian Pesticides and Veterinary Medicines Authority