Gully or hillside dam

Gully dams and hillside dams are the two main types of dams used for off-stream farm water storage. They are both used on sloping land and which one is chosen is dictated by the shape of possible sites.

Where there is a choice of sites, the final decision may depend on:

- relative expense of construction

- the required range of water uses

- aesthetics.

Gully dams

Gully dams take advantage of those natural valleys or depressions suitable for water storage. In some cases, it may be possible to utilise an erosion gully.

If the gully or depression is a waterway (as defined under the Water Act 1989) a licence is needed from your local rural water authority — both to construct a dam and to diver water.

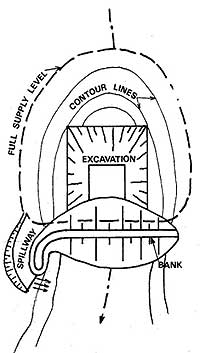

Where the gully is not a waterway, the banks of the proposed dam are built from soil material dug from an excavation contained within the storage area (see Figure 1). Gully dams are commonly used for storages ranging from 1 to 50 megalitres. They normally offer a low capital cost per unit of the stored water capacity.

Siting

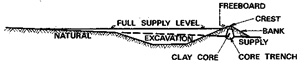

A narrow valley with a flat area widening out upstream from the bank site is ideal. If the floor slope is less than 1:20 (≈3°), a relatively low bank will store water over the natural surface for a considerable distance upstream (see Figure 2). This offers a cost advantage of a high storage to excavation ratio.

Size design and construction

Water yield from the catchment, and the proposed types of water use, usually govern size decisions. Because gully dams are more economic, water uses can be more easily extended to things like irrigation, fish farming and wildlife conservation.

All gully dams have a significant risk of failure be it due to:

- insufficient water

- excess water

- spillway erosion

- bank overtopping

- bank failure

- excessive seepage.

The demands for quality design and construction increase as banks increase in height. If banks are proposed to be higher than 3 metres — expert advice is essential. In all cases, considerable attention must be paid to compaction of the bank and consequently, the moisture content of the material when being packed into the bank.

Gully dams will generally have larger water flows moving into the storage than hillside dams. This is good for replenishment of dam water but it also demands careful design and construction of the spillway (and freeboard) to safely cope with flood flows.

Hillside dams

Hillside dams are usually selected because no suitable gully site is available. They are widely used in Victoria to ensure an accessible (non-reticulated) stock water supply.

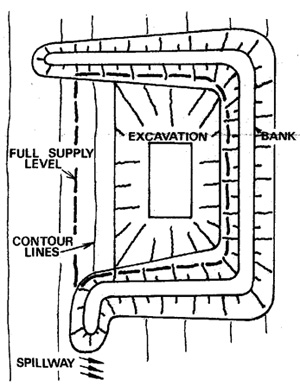

'U' shaped banks are constructed from soil materials dug from an excavation contained within the U (see Figure 3). Ideally the excavation will be fully contained within the water storage area of the dam. It is likely that naturally directed catchment flows will be inadequate to reliably provide water to the dam and graded banks will be necessary to intercept flows and direct them into the dam.

Before making a final decision on a hillside dam it is worthwhile considering reticulation from a smaller number of larger dams strategically located on the property. This is discussed in drought reserve dams.

Siting

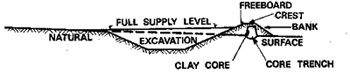

The storage to excavation ratio of hillside dams can be quite low (1.5 is common) and any way of increasing the value is desirable. Find a site that is as flat as possible — with suitable soil and catchment yield. With small storages of less than 1 megalitre, which are commonly used for stock water, storage to excavation ratios of less than 1.0 are likely if site slopes are steeper than 1:10 (≈6°).

This is shown in Figure 4.

Size, design and construction

The capacity of hillside dams is usually confined to the range: 0.5 megalitres to 10 megalitres. This is because of the economics of their low storage to excavation ratio, and the consequent limitations on types of water use.

Although hillside dams are less prone to failure than gully dams, they still require sound design and construction to be successful.

Further information

Widely varying circumstances apply on different properties and the information contained on this page should be used for general guidance only. Seek expert assistance with detailed planning when a decision to construct is made.

Your local water authority is able to supply additional information.

A guide to managing the safety of farm dams, Drought reserve dams.