Trickle flow pipes for farm dams

When dams are sited within drainage lines, trickle flows are diverted out of the natural drainage line and down an artificial 'spillway'. The steepness, exposure and soil condition of a spillway can allow trickle flows to stress the stability of the vegetative cover. Erosion can start and ultimately jeopardise the security of the dam itself.

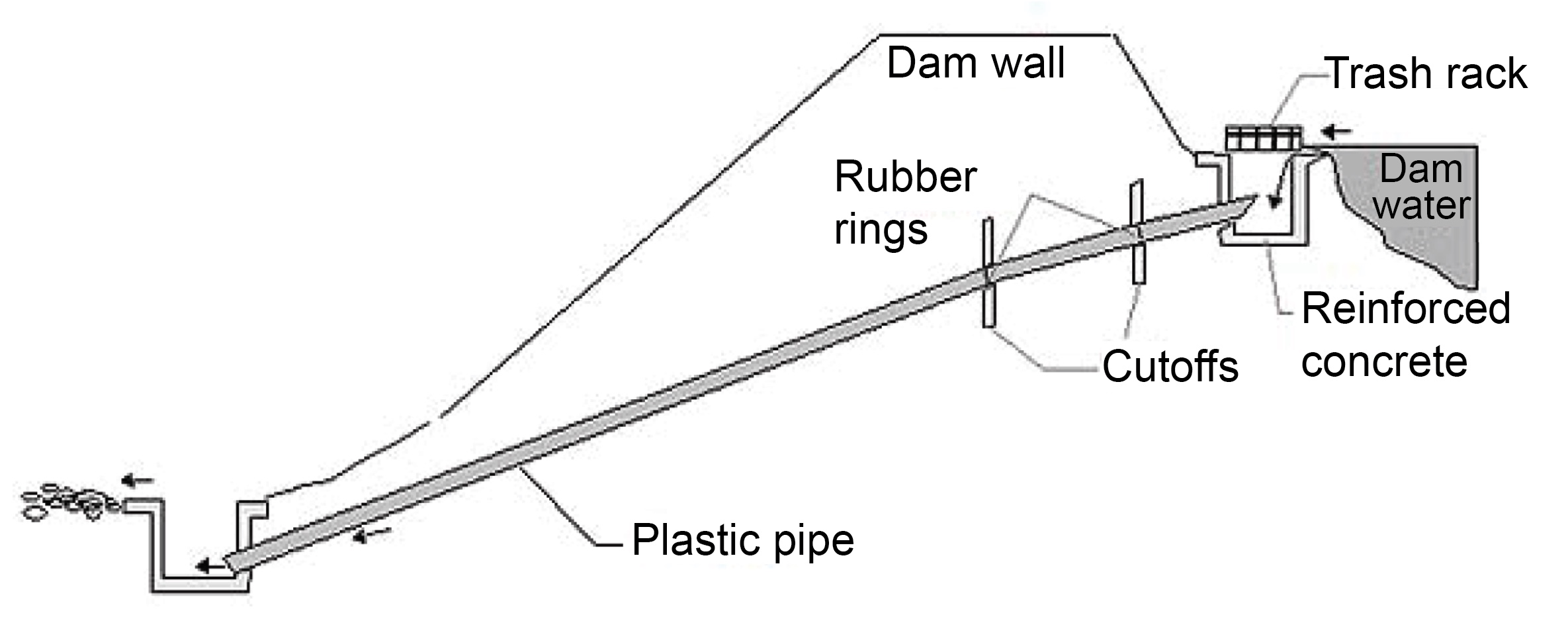

A trickle flow pipe can intercept these small steady flows and deliver them directly back to the floor of the drainage line.

What is a trickle flow pipe?

A trickle flow pipe is a low cost, easy to build structure, designed to intercept the small overflows at the top of the spillway and deliver it safely back into the base of the natural drainage line.

Pipe capacity

The size of pipe needed to carry the flows depends mainly on the effective head of water and on internal pipe friction.

A trickle pipe is not intended to carry all flows, but only those that are likely to cause regular saturation of the by-wash. Once the runoff flows exceed the capacity of the pipe, water moves down the spillway.

Design

The main components of a trickle flow pipe are:

- the inlet pit

- the pipe

- the outlet system.

Specific design will vary according to:

- dam design

- site topography

- soil type

- catchment size

- runoff characteristics

- gully floor stability.

lnlet pit

An inlet pit is recommended to increase the amount of effective head.

It should be set either into the top of the spillway or at the other end of the embankment. It should be set 100 to 150mm below the full supply level of the dam. Remember that the full supply level must be a minimum of 1m below the top of the wall.

A trash rack is necessary at the top of the pit where there are trees in the catchment of the dam.

Maintenance of the inlet pit and the likelihood of blockage with debris requires considerable thought. There are both advantages and disadvantages of fencing out the pit from stock in a grazed paddock.

Common designs utilise half of a 200 litre drum.

Pipe

A trickle flow pipe should not be laid along the spillway otherwise it will create erosion problems. If the existing spillway is already eroded — it may require repair or even rebuilding. In some circumstances it may be desirable to construct a new spillway at the other end of the dam wall.

Plastic pipe is commonly used, with a choice of either flexible or rigid construction. Corrugated flexible pipes allow variation in the slope and curvature of the trench but do have lower flow rates because of higher friction losses.

Elbows are undesirable as they constrict the internal diameter of the pipe and hence act as blockage points for debri (or turtles) moving into the pipe.

Pipe of diameter less than 150mm should not be used. Below this diameter they become quite susceptible to blockage.

Pipes should be buried to protect them from both sunlight and mechanical damage. They need to be buried. There must be a continual fall from the pit to the outfall.

Outlet system

Water can be discharged from trickle flow pipes at considerable velocity. It is necessary to have some mechanism to dissipate the energy of the water and reduce chances of scour and erosion.

Discharging directly to a heap of rocks is the simplest but filter-cloth should be used to prevent turbulent effects on the soil surface. A small stilling basin as a shallow pit is a more sophisticated and safer option.

Construction

- Peg the desired inlet and outlet locations.

- Dig a trench between the proposed inlet and outlet. The trench and pits can be dug by hand or by back hoe. Ideally the trench should have a constant grade. If using a rigid pipe, lay the pipes out before digging — taking care to get the proper alignment.

- Excavate pits for both the inlet and outlet structures — shaped to match the selected containers. The pits needs to be oversized by about 100mm. The bottom of the pits should be 150mm deeper than the trench to allow for a concrete base under the drum.

- Dig trenches for the cut-off walls. A minimum of 2 cut-offs are desirable. They should be about 100 mm thick and extend at least 1m from the pipe to inhibit longitudinal seepage. The easiest way is to dig a narrow trench across the pipe trench and fill it with concrete using a masonite formwork around the pipe. A rubber ring around the pipe at this point helps maintain a seal between concrete and the pipe. In dispersive soils, cut-off collars of gypsum-treated soil can be also be used to reduce the chance of tunnelling.

- Cut holes in the side of both the inlet and outlet drums near their bases to take the pipe.

- Cut the inlet pipe at a 45° angle as shown in Figure 2 to increase the intake circumference.

- Place rubber rings on the pipe at the inlet to help form a seal between the pipe and concrete.

- Pour sufficient concrete to make both inlet and outlet structure bases and ensure the tops of the drums are at ground level. Don't forget to use reinforcing mesh.

- Place drums in the inlet and outlet sumps. Position pipes in drums.

- Place reinforcing mesh around the drums and in the cut-off walls

- Pour concrete into the space between the walls of the excavation and the drum. Ensure the concrete and rubber rings make an effective seal with the pipe. In time, the drum rusts away leaving only concrete.

- Repack the soil by hand over the pipe as tightly as possible to inhibit seepage along the edge of the pipe.

- Install a removable trash rack over the inlet pit. A flat mesh over the sump may be insufficient as it can be readily blocked by accumulated trash.

Maintenance

- Pits should be checked regularly for blockages.

- The pipe outfall site should be checked periodically to ensure there is no scouring.