Centre pivot system capacity

System Capacity is the most important design criterion for centre pivot and lateral move (CPLM) systems. In the past many systems were under-designed to minimise capital cost and were not able to match peak crop water requirements. This has been the single main reason for CPLM failure.

What is system capacity?

System capacity is the maximum depth of water that can be applied to the entire irrigated area in one day, (a system capacity of 12mm per day day means the machine cannot apply more than 12mm in one day over the entire irrigable area.

It does not mean 12mm is applied in each irrigation event. The machine might be able to apply 24mm in a pass, but this will take two days to cover the entire irrigated area.

System capacity is the main criterion the pump, pipes and sprinkler design are based on, and for a given CPLM can be calculated as follows:

System capacity (mm/day) =

pump flowrate (ML/d) × 100

area irrigated (ha)

Example: a 400 m long centre pivot irrigates 50 ha. With a pump flow rate of 6ML/day, it has a system capacity of:

6 ML/d) × 100

50ha

= 12mm/day

What is managed system capacity?

The managed system capacity takes into consideration the water requirement of the crop, the application efficiency (AE) and the available operating hours of the system (termed pumping utilization ratio PUR).

The managed system capacity is the volume of water actually applied during an irrigation cycle divided by the area irrigated. The managed system capacity is less than the designed system capacity because of system losses and management practices that reduce the time that the machine is actually operating (maintenance, time of application). Given a known managed system capacity, the designer can then calculate the required flow rate and design the system.

If the system capacity is too low, the system may not be able to supply enough water to meet peak crop requirements. A higher system capacity ensures that the irrigation requirements can be met comfortably, even under extreme climatic conditions.

Machines with higher system capacities require a greater capital cost due to larger pipe sizes and pump capacities. A higher capacity machine will have a higher application rate at the outer end of a pivot which can cause water runoff if the application rate greatly exceeds soil infiltration rate.

Solutions for reducing impacts of higher application rates on the outer edge include the selection of sprinklers with the greatest wetted footprint and spreading out sprinklers perpendicular to the main pipe on outer spans.

Application depth

The depth of water that is applied in an irrigation pass depends on the system capacity of the CPLM and the speed setting of the machine.

Example:

- 12mm/d pivot completing its circle in 24 hours applies 12mm – if it completes the circle in 48 hours it applies 24mm.

To determine a suitable system capacity, the following factors must be considered.

Application efficiency (AE)

Application efficiency is the proportion of the water applied that the crop can use.

Under normal conditions (no wind, low evaporation - such as at night), the AE may be 95 per cent or higher. For calculating managed system capacity 90 per cent is a conservative AE to assume for peak crop water requirement conditions.

Operating hours

The Pumping utilisation ratio (PUR) is the proportion of time that the machine needs to operate to supply the peak crop water requirement. Continuous operation over many days should not be relied upon because breakdowns, power blackouts and other down-time will occur occasionally.

The recommended maximum PUR of:

- 0.85 is equivalent to operating for 6 days in 7, or 20 in 24 hours.

For most of the time when crop water use is less than the peak requirement, shorter operating times are needed.

Example:

- During the peak of the growing season, the pump averages six days use out of seven (with PUR of 0.85). The centre pivot’s estimated application efficiency is 0.90 (90 per cent). The designed system capacity of the system is 14mm/day.

Therefore, the managed system capacity is:

- 14mm × 0.9 × 8.5 = 10.7 mm/⁄day

A lower PUR may be desirable if operation primarily on off-peak electricity is planned (off-peak electricity hours of 88 hours per week is a PUR of 0.52), or where a more conservative operating regime is desired.

A conservative PUR requires a higher system capacity (and capital cost) but gives more flexibility to manage extreme events and down-time.

Peak crop water requirement

This is the highest rate of crop water use, usually expressed in mm/day, and managed system capacities must be greater than it. The peak water requirement is crop and location specific. A ‘crop coefficient’ (Kc) is used to express a crop’s relative water use:

ETc = ET0× Kc

The reference stand of pasture is given a Kc of 1.0. However, the appropriate Kc for mature actively growing lucerne, maize or sorghum is likely to approximate 1.2. This changes with the growth of the crop. A Kc of 1.2 indicates the crop requires 120 per cent of the water needed for perennial pasture.

The peak pasture water requirement used in calculating system capacity is not the highest daily ET0 but the highest average daily ET0 likely to occur over several days. Three days is generally considered to be an appropriate interval (Foley, 2008).

The frequency at which a particular three-day average daily ET0 recurs is a means of calculating the risk that a particular system capacity will not be able to supply enough water. Understanding how many extreme three-day peak crop evapotranspiration events per year will occur allows irrigators to determine their own level of risk in relation to their chosen CPLM system capacity.

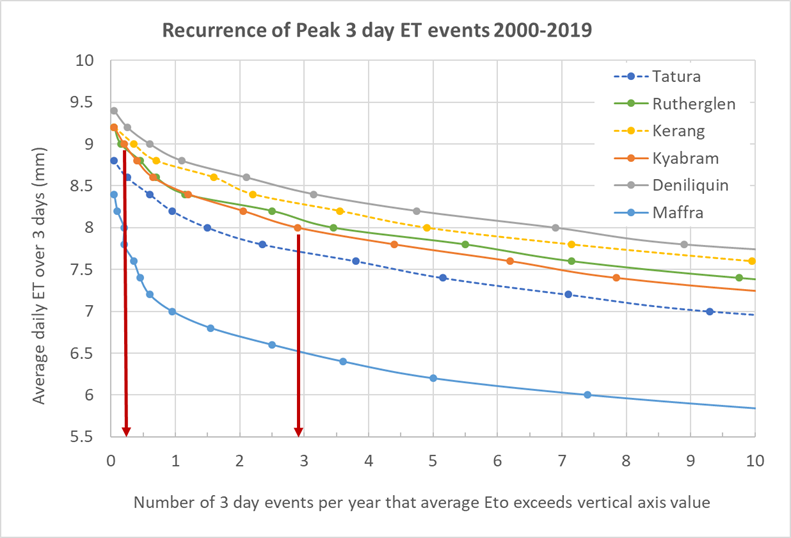

Figure 1 shows the frequency that peak three-day ET0 events occur at different locations in Victoria and southern New South Wales (NSW).

From Figure 1, at Kyabram 8mm of average daily ET0 over three-days (24mm total over three-days) is exceeded three times in a typical year. However, 9mm of average daily ET0 over three days is exceeded once every four years. That means a system able to apply 8mm/day is not able to keep up with crop water demand on three occasions in a typical season, where 9mm/day is rarely exceeded.

For Deniliquin, 8mm of average daily ET0 over three-days is exceeded seven times in a typical year and 9mm of average daily ET0 over three-days is exceeded between once every two years to once every year.

When calculating desired system capacity to grow perennial pasture at Kyabram, a three-day average ET0 of 9mm/day is recommended as the peak crop water requirement.

The desired managed system capacity for Kyabram can then be calculated as follows:

System capacity =

peak crop water requirement

AE × PUR

For the Kyabram example with peak crop water requirement of 9mm/day, an application efficiency of 0.9 and a PUR of 0.85, the minimum managed system capacity will be 12mm/day:

System capacity =

9mm/d

0.9 × 0.85

= 11.8 (≅12)mm/d

Therefore, the recommended minimum system capacity for perennial pasture at Kyabram is 12 mm/day.

If you are growing other crops like maize, sorghum or Lucerne instead of pasture then a ‘crop coefficient’ (Kc) for that crop should be used. This may require a higher system capacity.

Example:

Growing maize in Kyabram will have three-day average ET0 of 9mm per day with ‘crop coefficient’ (Kc) of 1.2 when in full canopy. The managed system capacity can be calculated as:

System capacity =

ET0 × Kc

AE × PUR

System capacity =

9mm/day × 1.2

0.9 × 0.85

= 14.1 14.1 (≅14 mm/day

Note: The system capacity necessary to meet maximum crop water requirement at Maffra (Gippsland) is significantly lower than for northern Victoria.

What System Capacity do I require for my CPLM?

The System Capacity should be sufficient to meet the crop water requirements for extreme ET0 events. The method described can be used to calculate the managed system capacity for different locations for your CPLM systems. A higher system capacity may be preferable but would require a higher capital cost. In determining the system capacity, consider what crops will be grown and include the maximum Kc in your calculations.

Having a lower system capacity does not necessarily mean pasture or crops will die in hot weather. Operating a lower system capacity machine continuously can maintain soil moisture levels. However, if the system capacity is lower than the peak water requirement, in times of peak crop water use, the crop will be extracting water from the soil faster than the CPLM can replace it, even when operating continuously. Under this scenario, crop growth will be reduced. In addition, if the CPLM then breaks down, it can be very difficult to replenish soil moisture levels to maintain optimal production.

With a CPLM, farmers typically aim to irrigate after 20 to 25 mm of pasture water use (ET0) has occurred (20 to 25mm ET0-R). Previous research suggested that if the soil moisture deficit on loamy soils increases to 35 to 40mm, pasture growth slows, and wilting may occur (Wood and Finger 2006).

A CPLM with a marginal system capacity requires a high level of management to avoid productivity loss, and major crop losses could occur with a breakdown or power outage. A more conservative (higher) system capacity gives additional security for limited additional capital cost.

System capacity and operating hours

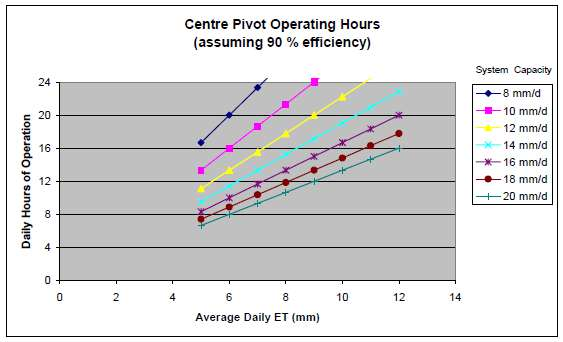

While the system capacity is critical to supply the peak crop water requirement, it also determines the operating hours necessary in normal conditions.

Figure 2 shows an 8mm/day system capacity CPLM applying 6mm needs to operate for 20 hours per day, in contrast to the 10mm/day system which takes 16 hours per day and 16mm/day system which takes only 10 hours per day to apply the same amount of water.

Low system capacity machines (10mm/d or less in northern Victoria) need to operate continuously to maintain (or minimise the decline of) soil moisture levels in peak demand times and need to operate for long periods in normal summer conditions. A conservative (high) system capacity allows more flexibility of operation and more security.