Poultry farm

In all Victorian planning schemes, a planning permit is required to use and develop land for a poultry farm with greater than 100 poultry (or 10 emus and/or ostriches). There are a range of zones where poultry farms may be permitted, and this is outlined in the Victoria Planning Provisions:

- Farming Zone

- Rural Activity Zone

- Green Wedge Zone

- Green Wedge A Zone

- Rural Conservation Zone

- Rural Living Zone

- Urban Growth Zone.

Local laws should be considered when determining if an activity is permissible.

For more information on permit requirements across zones in Victoria, download :

- Permit requirements across zones in Victoria (PDF - 84 KB)

[PDF File - 89.3 KB]

[PDF File - 89.3 KB] - Permit requirements across zones in Victoria (WORD – 84 KB)

[MS Word Document - 95.9 KB]

[MS Word Document - 95.9 KB]

Egg Farm Production Systems

Production cycle

The production cycle incorporates:

- Breeder and hatchery

- Pullet rearing

- Egg production (cage, free range or barn)

The production cycle begins with breeder farms and hatcheries, which produce day old chicks. Day-old chicks are then transported to pullet rearing sites, which are often co-located with layer farms. Pullets are reared to point of lay before being moved into layer sheds, where they begin producing eggs.

The layer hens are typically kept for 60-65 weeks before their productivity declines and they are culled (spent hens) for processing as meat, pet food or stock feed. Some egg farms compost or anaerobically digest their spent hens on-farm or at off-site facilities to produce energy and/or organic fertiliser/soil conditioner.

The location of egg farms is primarily driven by proximity to feed ingredients (mainly cereal grains) and population centres. In recent years, there has been a shift from cage production to free range and barn systems for the egg production stage.

Some egg farms may have an on-site egg packing shed or grading floor, whereas other farms send their eggs off-farm to a separate grading floor for cleaning, sorting and packaging. Some farms also have an on-site feed mill, while others buy prepared feed.

Industry supply chain

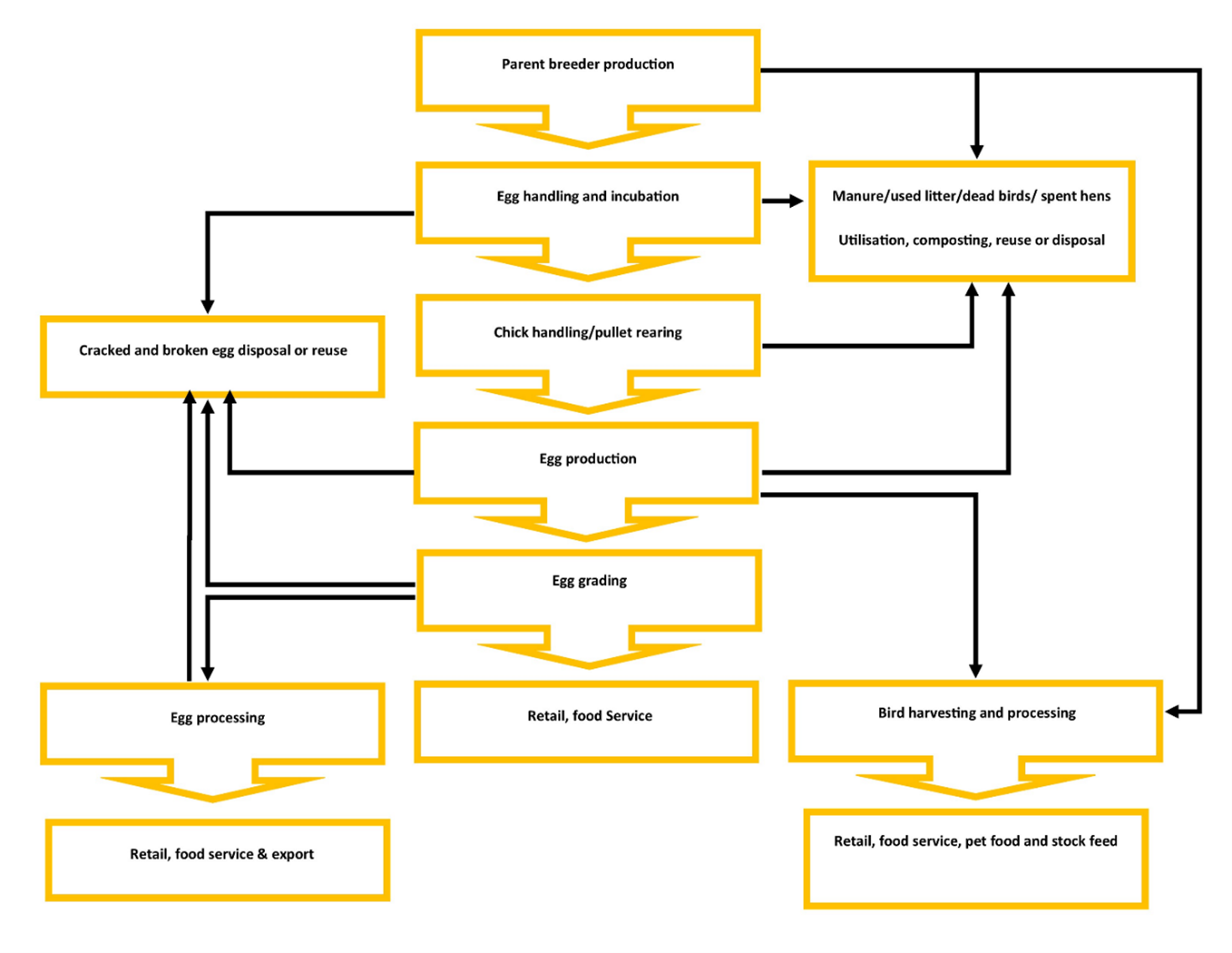

Figure 1 describes the structure of the industry supply chain from production to retail that include:

- on-farm feed milling,

- breeder farms,

- pullet rearing,

- egg production farms,

- on-farm egg grading facilities,

- management of by-products, including:

- cracked or broken eggs,

- manure from breeder, rearer and layer farms,

- wastewater from grading floors.

There are also a small number of manufacturing plants that process egg components into various products. As these are not typically located on egg production farms, they are not covered by Animal Production planning applications.

Types of facilities

Breeding Farms

Breeding farms keep hens and roosters to produce fertile eggs and are known as parent breeder production or secondary stock. The birds are housed in sheds with either litter, or slatted or wire mesh flooring so the manure collects underneath. The eggs are collected daily and stored for transport to a hatchery. The parent stock are productive for about 12 months. At the end of their productive life, they are removed for meat processing or other disposal methods. The used manure or spent litter is cleaned from the sheds at the end of each 12-month cycle and the process repeated. Most egg farms purchase day old chicks or pullets, rather than operating their own breeding farm.

The main by-products of breeder farms are dead birds, spent litter or manure, spent breeding stock with a small amount of broken/cracked eggs.

There are only a small number of breeder farms and hatcheries in Victoria. To protect biosecurity, they are located in isolated areas away from other poultry production, minimising the risk of disease outbreaks and consequent egg supply issues.

Pullet Rearing

The rearing of day old chicks to point of lay pullets (approximately 17 weeks of age) may occur on a specialist pullet rearing farm, or in a dedicated facility on the egg production farm. In both cases, the pullets are transferred to the egg production farm at the point of lay and thus no eggs are produced in this system. Pullets are reared in cage or barn systems.

The main by-products from pullet rearing facilities include manure, spent litter and dead birds.

Egg Production Facilities

Modern egg production (layer) farms range in size from small-scale free range operations with movable sheds up to sites with numerous large environmentally-controlled sheds that can house 40,000-100,000 birds each. Egg production facilities are described as either cage, barn or free range.

Cage Systems

Cage systems are located within sheds and consist of rows of raised metal cages. A large proportion of cage layer sheds in Australia are environmentally controlled, with ventilation systems to exchange air (tunnel ventilation) and maintain acceptable indoor thermal conditions and air quality all year round. The remainder are cross flow ventilated or naturally ventilated.

Most cage systems have manure belts under the cages, allowing manure to be removed when required, typically 2-3 times per week. If manure belts aren’t installed, manure accumulated in the shed and is moved at the end of the production cycle. In locations that experience cold wet winters, belts can be fitted with a drying system that removes moisture from the manure to improve the shed environment and production. Cages are designed to allow eggs to roll clear of the hens for automatic daily collection via conveyor belts. Some cage systems are fitted with additional equipment for the hens, such as nest boxes, perches and scratch-pads. These systems are referred to as furnished cages.

Barn Systems

Barn systems consist of sheds in which the hens are free to move. Most barn systems have floors covered with litter with perches provided. Some barn sheds are designed with slatted floors over manure removal belts. A variation of a barn shed is an aviary shed, where poultry are housed on several levels including the shed floor with litter and sometimes manure removal belts. Some of the barn systems also use tunnel ventilation and most larger sheds have automated feeding and drinking systems.

Free Range Systems

The housing used for most free range production is essentially the same as the barn systems, but the birds also have access to an outside range area. The sheds are fixed and the internal infrastructure is the same as that used in barn production.

Some smaller free range operations use mobile sheds/caravans that are moved regularly around a paddock. There are also some systems where larger sheds on skids are moved between locations.

Egg Packing and Grading Facilities

From the layer sheds, eggs will either go direct to an on-site grading facility (floor) or a packing shed. If they are sent to an on-farm packing shed, they will then be transported to an off-farm grading floor. At these facilities, cracked, dirty and unsuitable eggs are removed. The remaining eggs are cleaned, weighed and sorted before packing for dispatch.

Waste products from grading floors and packing sheds include small volumes of wastewater from the washing and sanitising process, cracked/broken eggs and rejected packaging.

Victorian Low Density Mobile Outdoor Poultry Farm Planning Permit Guidelines - June 2018

These Guidelines provide information and direction to applicants and planners for assessing planning permit applications to establish or modify a low density mobile outdoor poultry farm. They outline what planners should expect in the application, and present key decision guidelines to support assessment of the application.

These Guidelines set out the eligibility requirements for a simplified planning assessment process based on the farms having low environmental and amenity risks.

These Guidelines apply to a planning permit application for poultry farms for chicken egg production (farm capacity of no more than 5,000 birds). Additional planning requirements are outlined in the Victorian Low Density Mobile Outdoor Poultry Farm Planning Permit Guidelines that must be met.

Victorian Low Density Mobile Outdoor Poultry Farm Planning Permit Guidelines ![]() [PDF File - 594.5 KB]

[PDF File - 594.5 KB]

Victorian Low Density Mobile Outdoor Poultry Farm -Supporting Documents

Development plan template

A development plan contains the information that planners should expect from a planning application. It outlines the way in which the facility will be sited, built and managed to meet the objectives and standards of the guidelines.

A template is provided below to assist applicants in creating their plan. The template includes guidance notes/examples and checklists to assist applicants in identifying the information to include in each section.

LDMO Poultry Farm Development Plan ![]() [MS Word Document - 1.9 MB]

[MS Word Document - 1.9 MB]

LDMO Poultry Farm Development Plan ![]() [MS Word Document - 1.4 MB]

[MS Word Document - 1.4 MB]

Application checklist

The Application checklist has been developed for planners to ensure that all information required by the Low Density Mobile Outdoor Poultry Farm Planning Permit Guidelines has been included in a planning permit application.

The checklist is intended to be used in conjunction with the Victorian Low Density Mobile Outdoor Poultry Farm Planning Permit Guidelines.

Further information on Poultry farms

PPN87: Preparing a planning permit application for animal production

This practice note provides information and guidance for applicants about preparing a planning permit application to use and develop land for animal production.

View PPN87 at the Department of Transport and Planning.

Egg Industry Environmental Guidelines, 2nd Edition – May 2018

View the National Egg Industry Environmental Guidelines at Australian Eggs.

Contact

For further information contact the Agriculture Victoria Planning and Advisory Service for all agricultural land use planning enquiries on agvic.planning@agriculture.vic.gov.au.